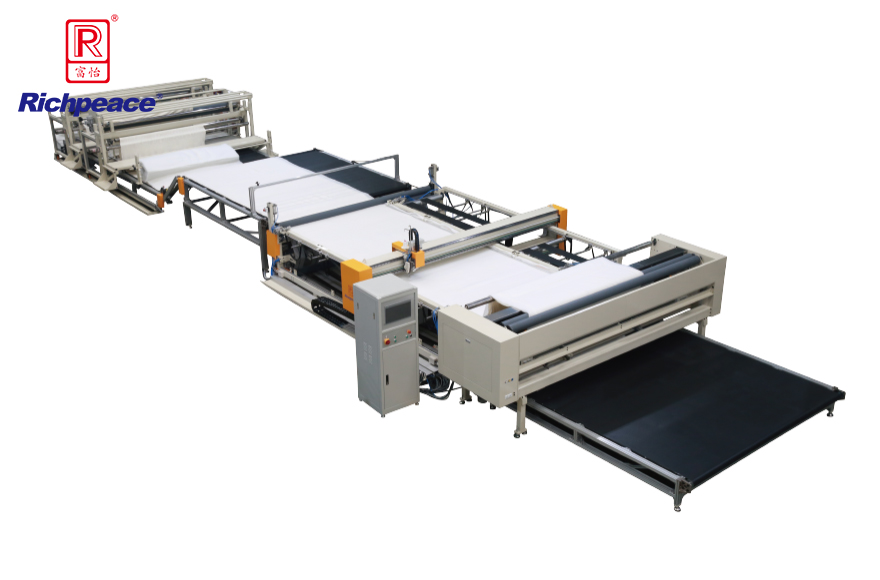

1. Automatic production line from material feeding in auto-alignment to 4-side sewing and trimming.

2. Auto feeding mechanism: Automatic material loading and feeding system and auto-alignment device ensure the material edges in equal. The feeding shelf is movable and adjustable to meet different requirement.

3. Buffer mechanism: Equipped with a set of laser lights to assist workers in adjusting the material position before material moving to sewing area.

4. Automatic sewing mechanism: Max. sewing speed is 3000 rpm, and recommended working speed is 2000-2700 rpm. Lifting sewing head, Japanese Jumbo rotary hook.

5. Auto cutting mechanism: Equipped with cross cutting device and vertical side cutting device to trim the edges, in labor-saving.

6. Material width within 1500mm-3000mm, clamping size is adjustable. Single side cloth consumption is 20-30mm ( left / right side), and distance from clamp to needle is 20mm, so the final distance between stitch line to the fabric edge is around 50mm.

7. Optional device: Automatic bobbin changer to improve production efficiency.