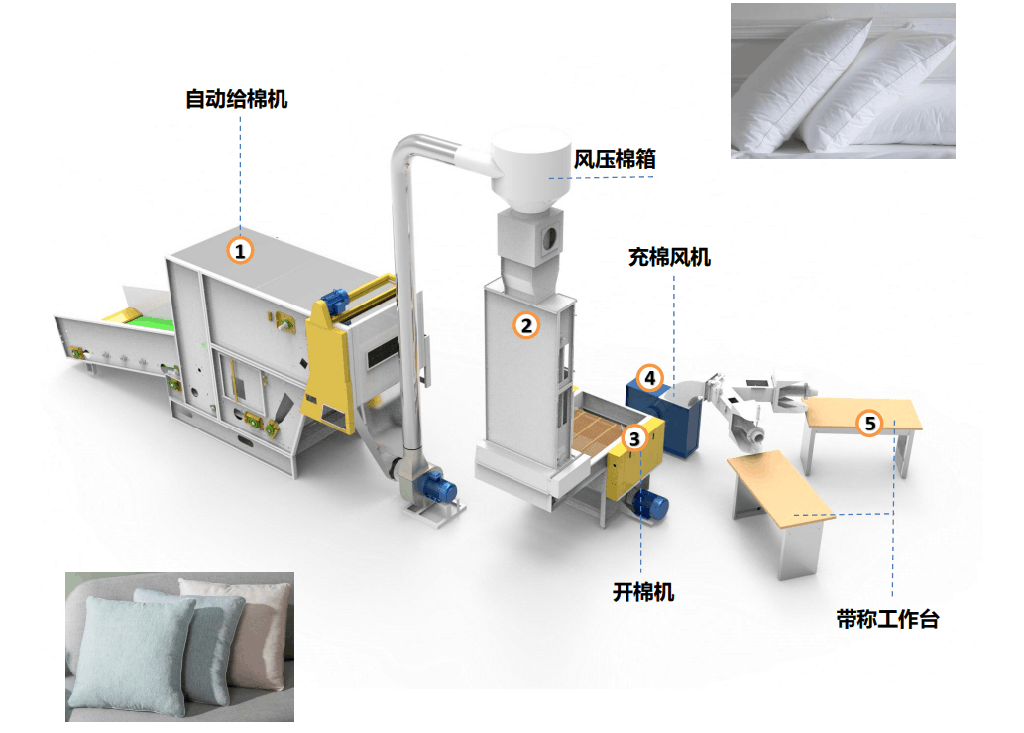

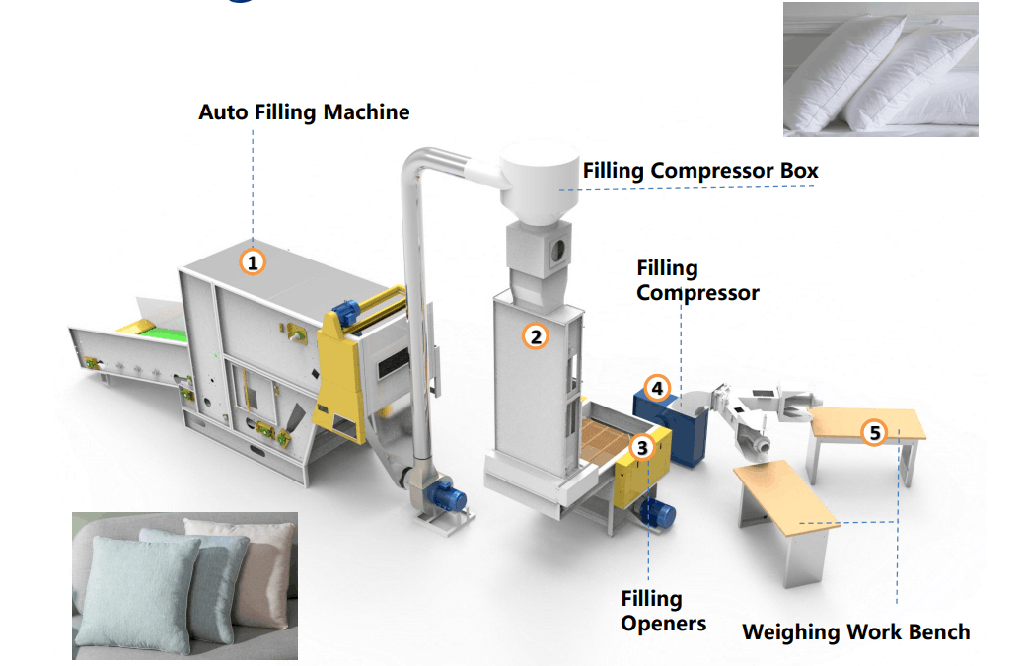

Application:

1. This production line mainly for 6D or above synthetic fiber opening and weighing, then filling for pillow, bolster pillow, cushion or similar products.

2.Filling hole open width is 20cm or above, opening speed at 200kg/hour.

3.PLC program control, auto feeding, auto case insertion fixture.

4. One person can operate the whole production line, save labour, no skillful worker required.

5. Weight presetting function,tolerant within土10% approx.

6. Multiple open rollers,100% open rate of 6D above synthetic fiber, no damage on fiber crimp and smoothness.

7. Filling products are fluffy, good resilience and soft hand feeling.

一. Auto Filling Machine

1. Auto filling machine, also named as Bale Opener.

2. Mainly used for preliminary opening large bales of fiber raw material and automatically sent to the opener instead of manual feeding, more safety work.。

3. A bale of about 300 kg of material (can be customized according to customer needs) can be put on conveyor belt of bale opener at a time, save labour cost.

Parameter | Machine Size | 5260X1490X2240MM | Weight | 1500KG |

Power | 4.4KW | Voltage | 3-phase 4-wire 380V |

二. Filling Compressor Box

1. Pre-opening fiber or raw material evenly lay on the conveying curtain, so that opening machine can evenly feeding the filling.

2. Optical sensor adopted, once filling in the box is full, feeding from the bale opener will be stopped, so as to prevent compressor or the opener from blocking due to excessive fiber feeding.

Parameter | Machine Size | 1260X1450X1240MM | Weight | 1500KG |

Power | 0.25KW | Voltage | 3-phase 4-wire 380V |

三. Filling Openers

1. Filling Opener, also called Fiber opener.

2. Mainly for the opening of raw material, polyester and polypropylene polyester fiber.

3. Rollers with anti-winding device, and conveyor belt with anti-deviation device, reduced maintenance and cleaning frequency, improved equipment reliability.

4. Rollers are processed with dynamic balance, machine without vibration, and low noise level during operation, no machine fixed required.

5. Multi-head dense gear and the tension generated by reverse operation of the multi-gear rollers, enhanced the opening effect, made the fiber can achieve the best fluffy effect.

Parameter | Machine Size | 1700X1700X1100MM | Weight | 550KG |

Power | 4KW | Voltage | 3-phase 4-wire 380V |

四. Filling Compressor

1. Connect the filling opener, fill the opened fiber into bolster pillow or pillow case through the centrifugal effect.

2. Filling feeding open with clamping fixture, replaced manual holding of the feeding pocket during filling work, automatically released the fixture when filling is finished.

3. Auto-switch filling port with the preset filling time, two filling ports alternative feeding.

4. Filling port can be connected to weighing or a vibration workbench for finishing work while filling.

Parameter | Machine Size | 1800X1840X2200MM | Weight | 140KG |

Power | 3KW | Voltage | 3-phase 4-wire 380V

|

五. Weighing Work Bench

After filling feeding completed, weighting the filled product.

Parameter | Machine Size | 1200X1020X830MM/PC | Weight | 20KG/Set |

Power | 5W/SET | Voltage | 3-phase 4-wire 380V |