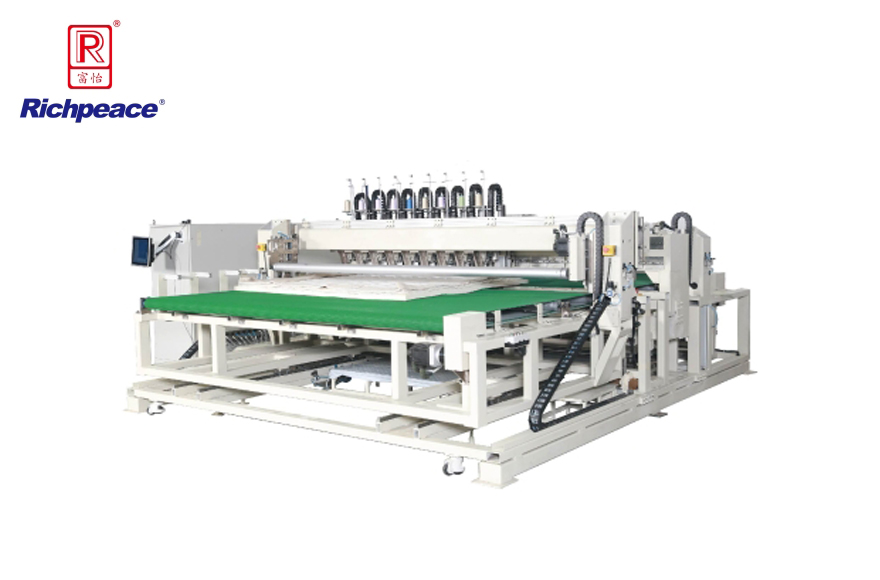

1. 9 machine heads are evenly located, can be lifted up and down individually, and computer control works at the same time. Able to select one or more machine head on or off. Machine heads spacing can be adjusted freely within a certain range. High speed automatic lifting machine head, suitable for various thickness sewing products requirement. Automatic upper & lower thread trimming feature.

2. Using long presser plate, by multi-points air cylinder pressing. Automatic pressed down when bar-tacking, ensure each bar-tacking result uniformly made, automatic lifted up after bar-tacking finished.

3. Feeding and discharging with belt driven, adjustable two ends, suitable for a certain range with various product width. Equipped with adjustable air compression control, computer control material movement, ensure precision bar-tacking.

4. Single operator, auto positioning, multi-heads run bar-tacking in one time to have single row of bar-tacking effect requirement. Conveying belt driving material mat movement without manual interference, greatly improved efficiency.

5. Freely design of bar-tacking pattern, realize products variety.

6. Intelligent system extendable: connecting with automatic production line, third-party automation device connection port control.

7. Machine equipped with DLC diamond coating needle bar and rotary hook shaft, wear resistance, able to work normally under high speed without lubrication or only minor lubricated.

8. 6-axis servo system + high precision lead screw driven, ensure high precision sewing.

9. SMC atomized oil injection to realize automatic lubrication.

10. Richpeace sewing computer control system, ARM core + LINUX system.