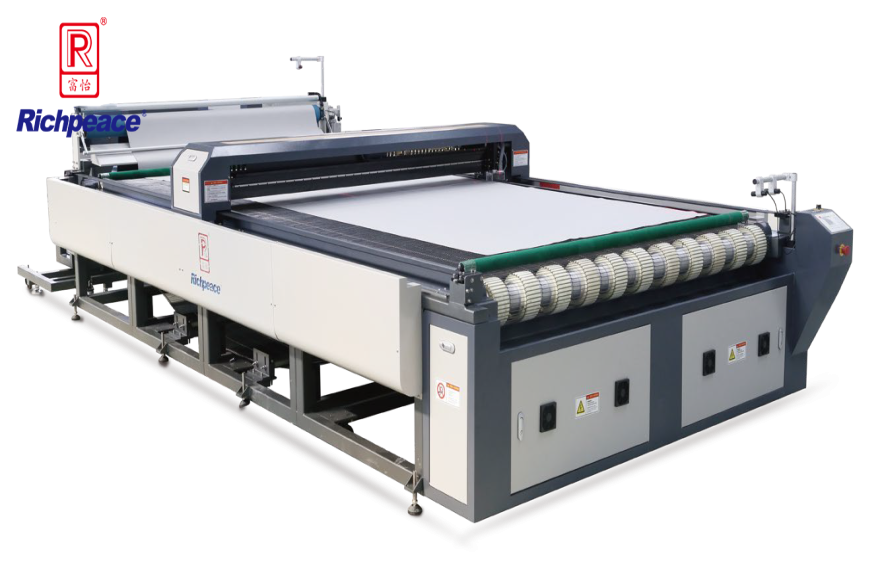

1. Large format with auto-feeding system, satisfied the material feeding with whole roll of fabric and cutting, benefit the enterprise with higher productivity.

2. Constant light pathing design, ensure any position with consistent light source for large format laser cut, also keeping the consistency of processing effect.

3. Machine body is split design, easy for transportation.

4. Software can directly connect with AutoCAD, CorelDraw, Richpeace Garment CAD, and realizes direct output of original drawings to engraving images.

5. T-304 stainless steel mesh conveyor belt, custom made is possible according to requirement.

6. Equipped with 3.5 inch 65K color screen, visually display product image preview and processing status. Suitable for custom made apparel, made-to-measure, sofa, toy, cap & shoes, position cutting on textile printing fabric, automotive interior, advertising, etc industries.

7. Two types of communication port available for customer choice, support USB 2.0 port, for connecting USB storage Read/Write and system upgrade via through this USB port. And LAN network communication with computer, more convenient, safe and reliable.

8. Adopted S-curve acceleration & deceleration, speed adjustable planning, satisfied cutting stable start/stop and high-speed processing both requirements.

9. Optional with Supernest software, able to output with extra long file in one time, automatic cutting by section.

10. Optional with fully automatic material feeding rack, realize operation in one time, fully automatic cutting.

11. Optional with dual heads laser, higher efficiency, twice the working speed.

12. Linear guide rail moves in XY direction.