- Home

- PerLam-SewPer Line

- PerLam-SewEmb Production Line

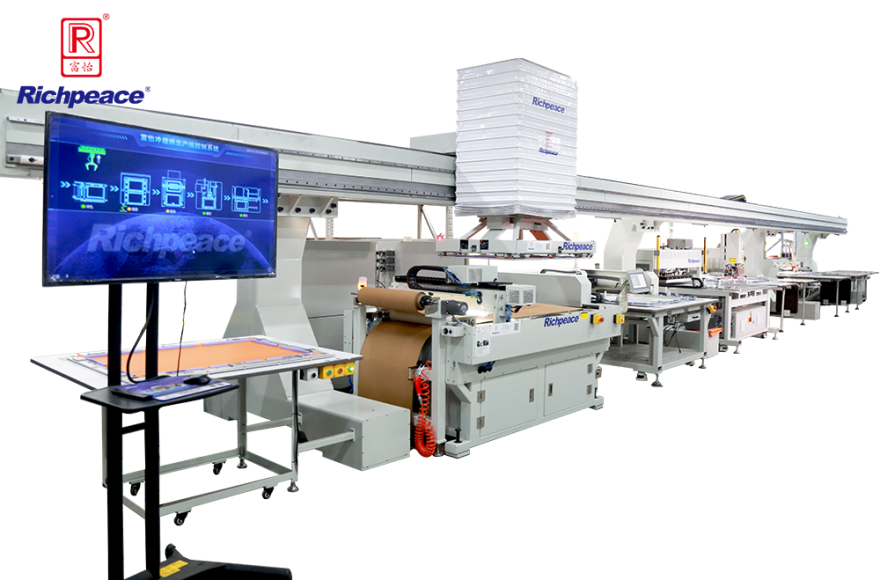

PerLam-SewEmb Production Line

/shop/perforation-lamination-sewing-embroidery-machine-1902此产品已停产。

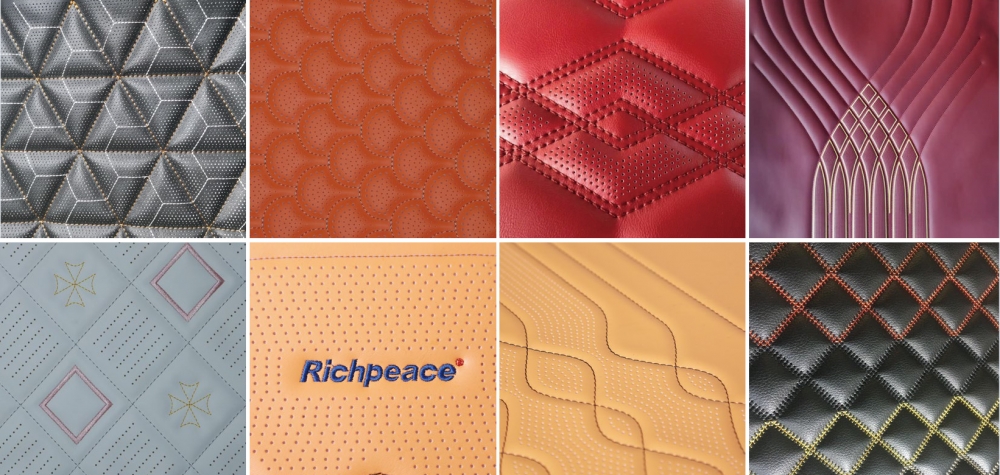

Richpeace Automatic punching, replicating, sewing, embroidery production line is a new concept, set leather punching, testing, compounding, sewing, embroidery five processing units as one of the automatic production line. The seamless sequence transfer of clamping fixture between each process unit is realized by automatic sequence transfer process. The whole line only needs a manual participation assistance, can easily realize the normal operation of the whole line. Punching station can achieve the max. punching speed of 1000 holes/min, detection station can be matched accordingly to the pattern of punching, single piece composite time can be completed in 10 seconds, the max. sewing speed of 2500RPM, embroidery speed of 1200 needles/min.

Richpeace Automatic Perforation Machine

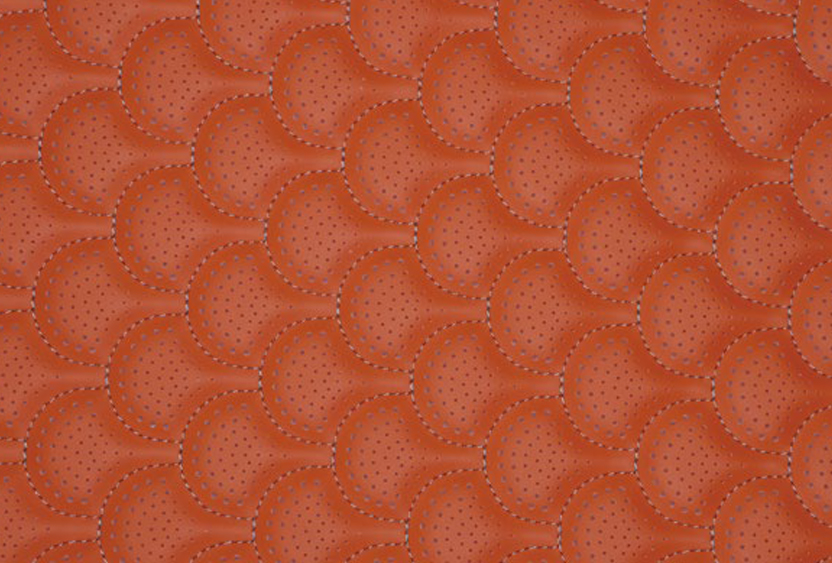

1. Richpeace Automatic Perforation Machine has a compact and reasonable design and a small footprint.

2. Empty box type collecting dander, no residue on the surface of the fabric,vacuum cleaner intermittent work, energy saving.

3. Horizontal movement of the head, maximum punching speed of 1000holes/min.

4. Each punching head has 4 sizes: 0.8mm, 1.0mm, 1.2mm, 1.5mm. Four punching knives can switch freely. Able to make gradient hole design.

5. There is no need to stretch the material during process. With various template shaping technology, it can solve the problem of special-shaped pieces clamping.

6. Set automatic the underneath paper feeding length, save the paper cost.

7. Equipped with Richpeace 3rd generation of punching machine control system, optional intelligent code scanning, quick retrieval and positioning operation, the management of process is more orderly.

8. Richpeace self-developed CAD software for Perforation is easy to learn, which solves the problem of pattern making.

Richpeace Visual Inspection Machine

1. Richpeace self-developed electronic control system.

2. Machine vision technology is used to accurately locate defects in the production process.

3. The high-pressure blowing system automatically dispose of the waste that is not flushed after identification.

4. Adopt 10 inch LCD touching screen.

Richpeca Leather Lamination Machine

1. Automatic feeding, cutting, compounding at one go, without manual intervention, leather can be automatically compounded.

2. Roll feeding, reduce feeding times, improve the film compound efficiency.

3. Richpeace independent leather compound electronic control system.

4. Upper heating plate to ensure uniform heating, lower plate with high density elastic material to ensure uniform pressure, with high consistency of composite effect and bond strength.

5. 10 inch high-definition color screen, easy to operate.

6. The upper and lower heating plates adopt hydraulic system to ensure the output strength of compound pressure.

7. Branded servo motor drive, high precision linear guide rail to ensure the composite precision of materials.

8. Suitable for various omentum hot melt adhesive compound, no colloid overflow, avoid dirt adhesion, smooth and beautiful products.

9. Light screen curtain safety protection, to avoid worker injured caused by heating board during operation.

10. Automatic frame pressing, fixed material, reduce labor intensity, ensure composite accuracy.

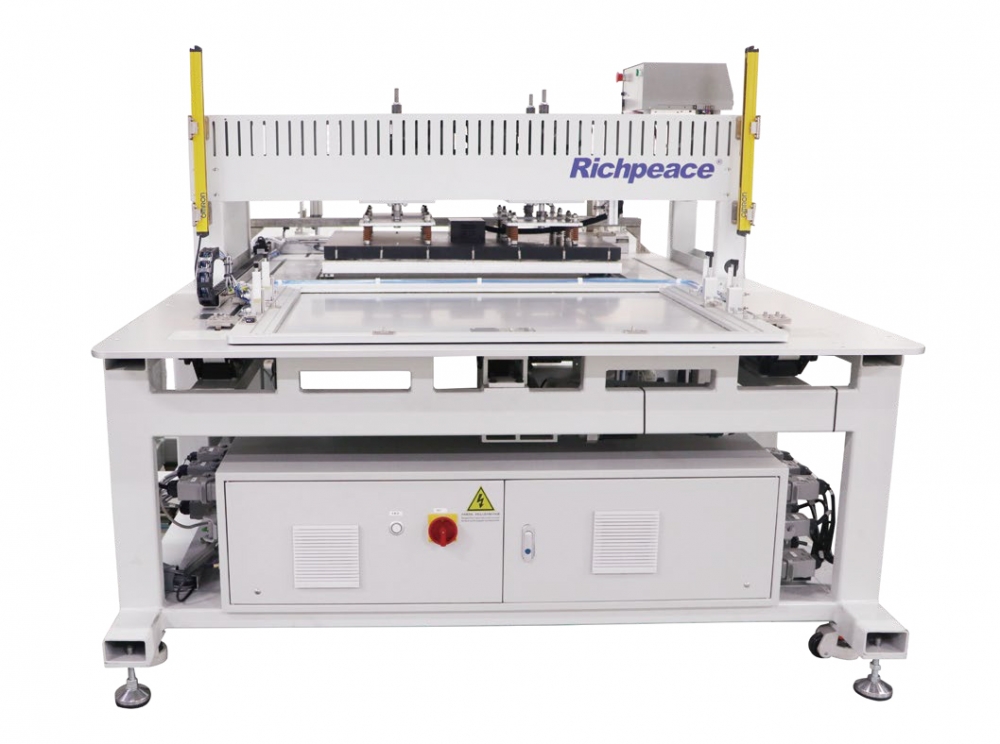

四、富怡全自动360°单针旋转缝纫机

1. Richpeace self-developed electronic control system for sewing, with ARM kernel + LINUX system.

2. Adopt independent drive 360°rotating head to avoid quality difference of positive and negative stitching.

3. Head pneumatic lifting, up to 100mm, easy to change frame, conducive to step sewing, higher equipment safety.

4. Branded servo motor drive, high precision linear guide rail transmission, to ensure the precision of the pattern.

5. DLC diamond-like coating is used to treat the needle rod and rotary spindle, which is wear-resistant and can meet the normal operation of high speed with little oil or without oil.

6. 10 inch of high definition screen, easy to operate.

7. With automatic pneumatic thread cutting, surface thread breaking detection, bobbin thread counting function, tooling template in place detection function.

8. The platform support structure ensures the flatness and accuracy of products under high speed operation.

9. SMC atomized oil injection, automatic oiling for the main transmission parts.

10. Insert the USB port through the USB disk to input pattern, stitches file capacity is large.

11. Optional Richpeace sewing CAD software, arbitrary design, easy to learn.

Richpeace Automatic Embroidery Machine

1. Richpeace three advantages: Software, Electronic control, Mechanical integration, with independent intellectual property rights and customization capabilities.

2. ARM + LINUX framework under the industrial control system: independent research and development, flexible expansion, strong compatibility, reliable and stable.

3. Richpeace self-developed embroidery software can match perfectly with Automatic Embroidery Machine.

4. Self-developed and produced stabbing mechanism; rotary shuttle mechanism and wire picking mechanism, to ensure the accuracy of size and quality stability. Aluminum alloy CNC processing, special surface treatment.

5. Thread cutting system: motor dynamic thread cutting, controllable thread length, higher efficiency, mute, improve embroidery quality and productivity.

6. The spindle, X and Y are all driven by servo motors.

7. The frame adopts high quality steel, high rigidity, horizontal platform welding, large gantry milling machine, double beam structure, precision and strong.

8. The platform is made of quality materials, high hardness, high strength and wear-resisting, good flatness, and it is molded by a CNC machining center.

六、Richpeace Automatic Station Transfer System

1. Richpeace self-developed electronic control system.

2. The pickup part adopts electromagnet adsorption to ensure that pickup frame will not be deformed.

3. Improve the safety factor in the process of movement.

4. Longitudinal servo motor + screw sliding platform module, more stable movement, up and down 600mm height

5. Horizontal servo + rack and pinion, the total movement distance up to 17 meters

| Model | RPCE-L-P-1-600×900-G-P4-1P220 RPFP-L-DI-900×600-PG-1P220 RPAS-NM-C-1-900×600-B-HM-0-AL-1P220 RPAS-L-R-1-900×600-A-IS2-VR2-LH100,RH360,UTC-1P220 RPCE-NM-FE-1-900×600-B-F9-VR1-NA-1P220 RPFP-L-DI-1-17000×50-SGSF-1P220 |

| Working Area | 600mm×900mm 800mm×1200mm |