1. Single-man operation tooling is automatically pressed.

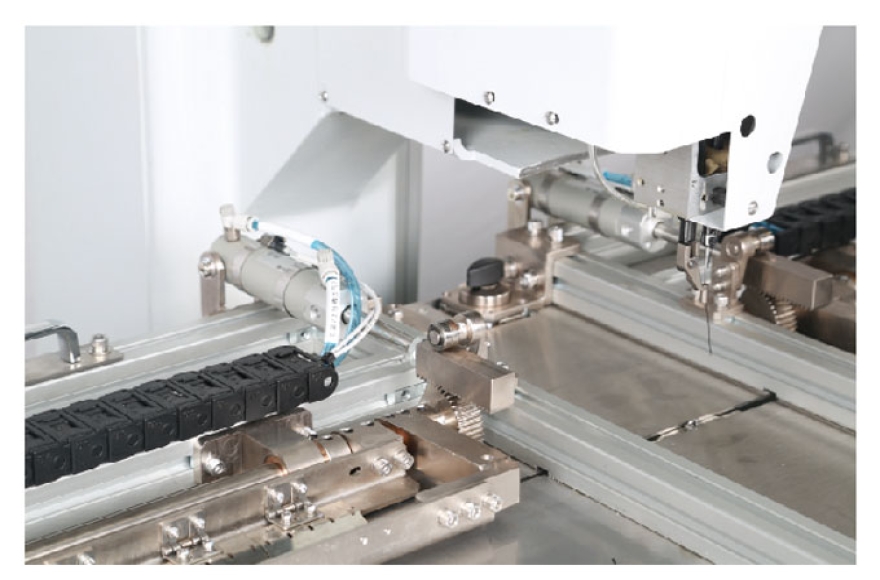

2. The tooling and the machine are connected by a positioning pin and a thumb-turning clamp, which can achieve the purpose of quick replacement.

3. The working area is equipped with a safety sensor protection device to ensure that the worker's personal safety is protected to the greatest extent during the work.

4. The self-developed left and right symmetrical head ensures the precision and quality of the sewing process.

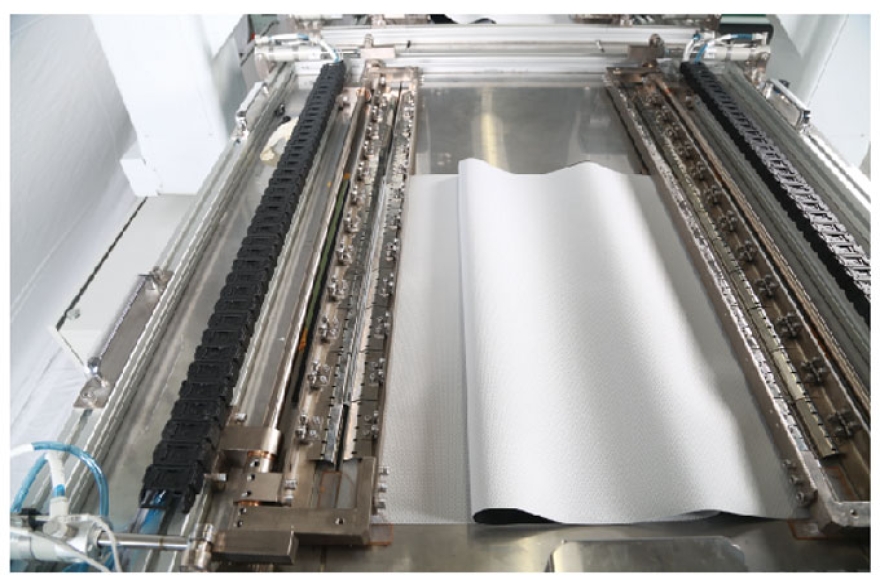

5. Two sewing work areas, A/B two work surfaces, run alternately. To achieve non-stop, continuous sewing, the machine runs at full load, and the production efficiency is doubled.

6. The self-developed high-precision fixture can accurately position and fix the fabric to ensure the sewing quality.