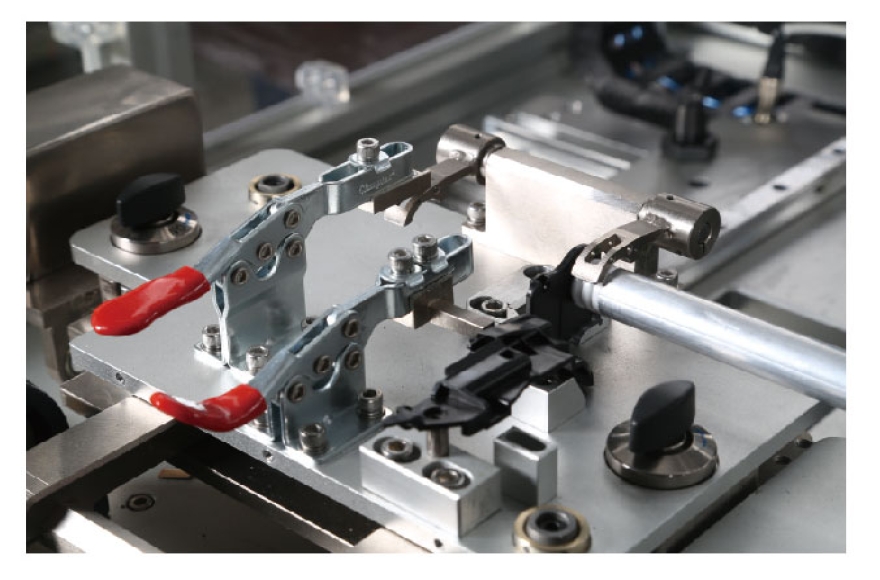

1. The positioning pin and 1/4 knob are used to realize the quick change of the tooling, the conformal positioning function, the tooling is more convenient to place, and the pneumatic clamp realizes the automatic pressing of the tooling.

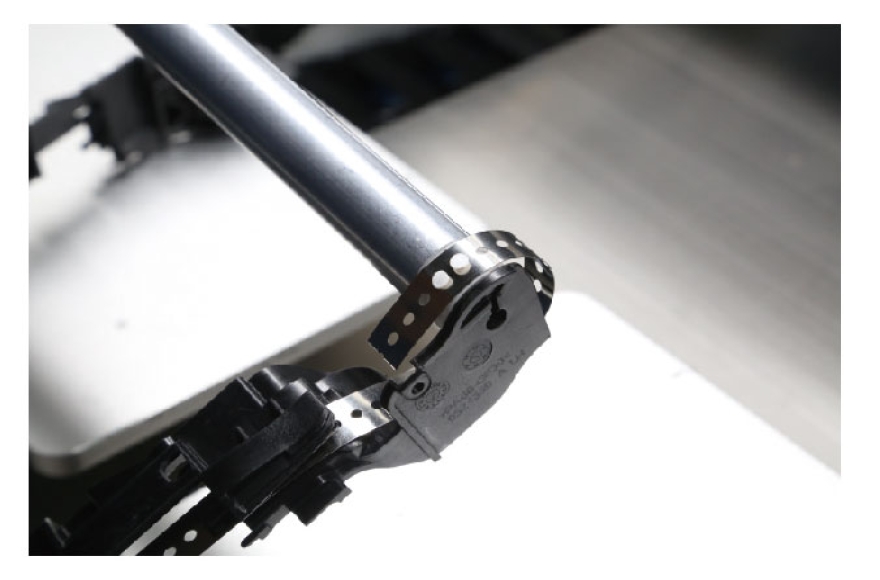

2. The installation of the hot-melt head is tightened by manual screws, which can realize the quick change of the hot-melt head of different products, and avoid the damage to the cylinder caused by high temperature through the heat-dissipating parts between the hot-melt head and the cylinder.

3. The trough is designed to open and close automatically, which can be automatically opened and closed by the cylinder.

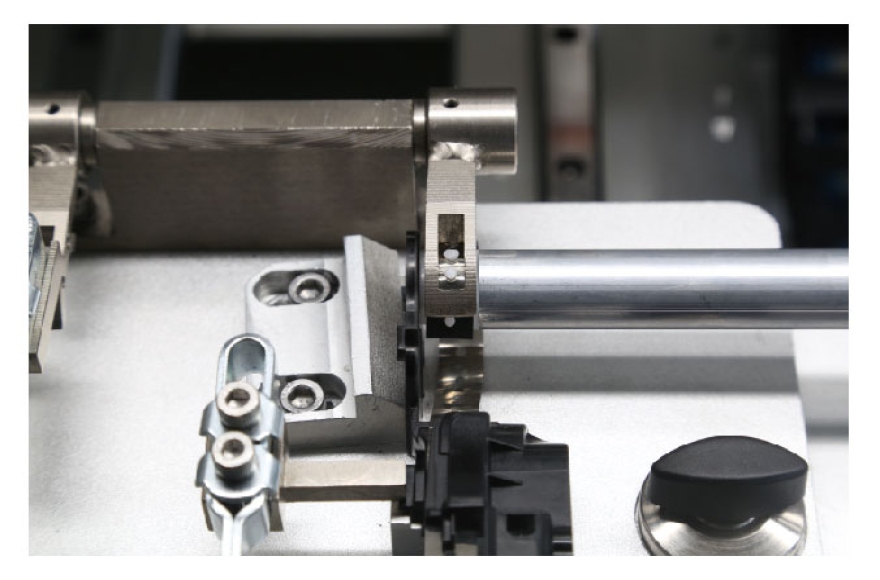

4. The automatic feeding and returning function of the equipment is realized through the drive of the long cylinder.