▲

▼

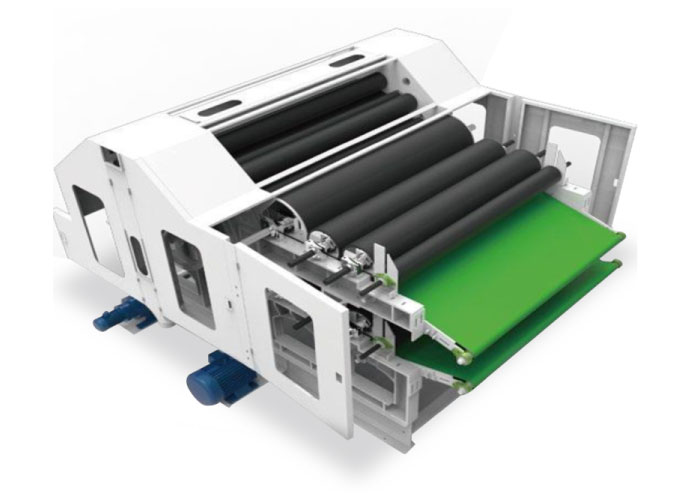

Carding Machine

.png)

Please wait a moment. The video is loading...

×

Related Products

←

No association.

→