-

A real-time dashboard that provides a rich component library, allowing users to customize and create their own exclusive IoT Dashboard.

-

Custom Rule Chains, flexible and adaptable to different scenarios,

-

Customers represent independent business entities. Customers are isolated by tenants, meaning different tenants have different customers.

-

Alerts are triggered for incoming actions, attribute updates, device malfunctions, and user errors.

-

Supports the RS232/RS485, CAN, USB and Ethernet Interface.

-

Device data is collected and uploaded to the platform using the MQTT protocol, enabling real-time monitoring of device operating status and data.

-

MQTT, TCP, COAP, HTTP, NB-IOT and MODBus protocol.

-

4G, WiFi and Zigbee Module.

Three Major Application Values of the Real-Time Energy Consumption Monitoring System

Automatic Meter Reading to Reduce Labor Hours Digital Management to Reduce Costs and Improve Efficiency Energy AI Brain for Intelligent Adjustment

By integrating sensors, the system enables automatic meter reading for water, electricity, and gas energy consumption. This solves the issues of untimely and inaccurate manual meter readings, ensuring precise and efficient data collection.

The system helps enterprises establish a digital energy management framework tailored to energy usage and daily operational needs. This reduces personnel input, lowers operational costs, and enhances overall efficiency.

Through advanced optimization algorithms and expert models, the system enables comprehensive perception and optimization of energy equipment and systems. This improves energy utilization efficiency by making intelligent adjustments to energy settings and operations.

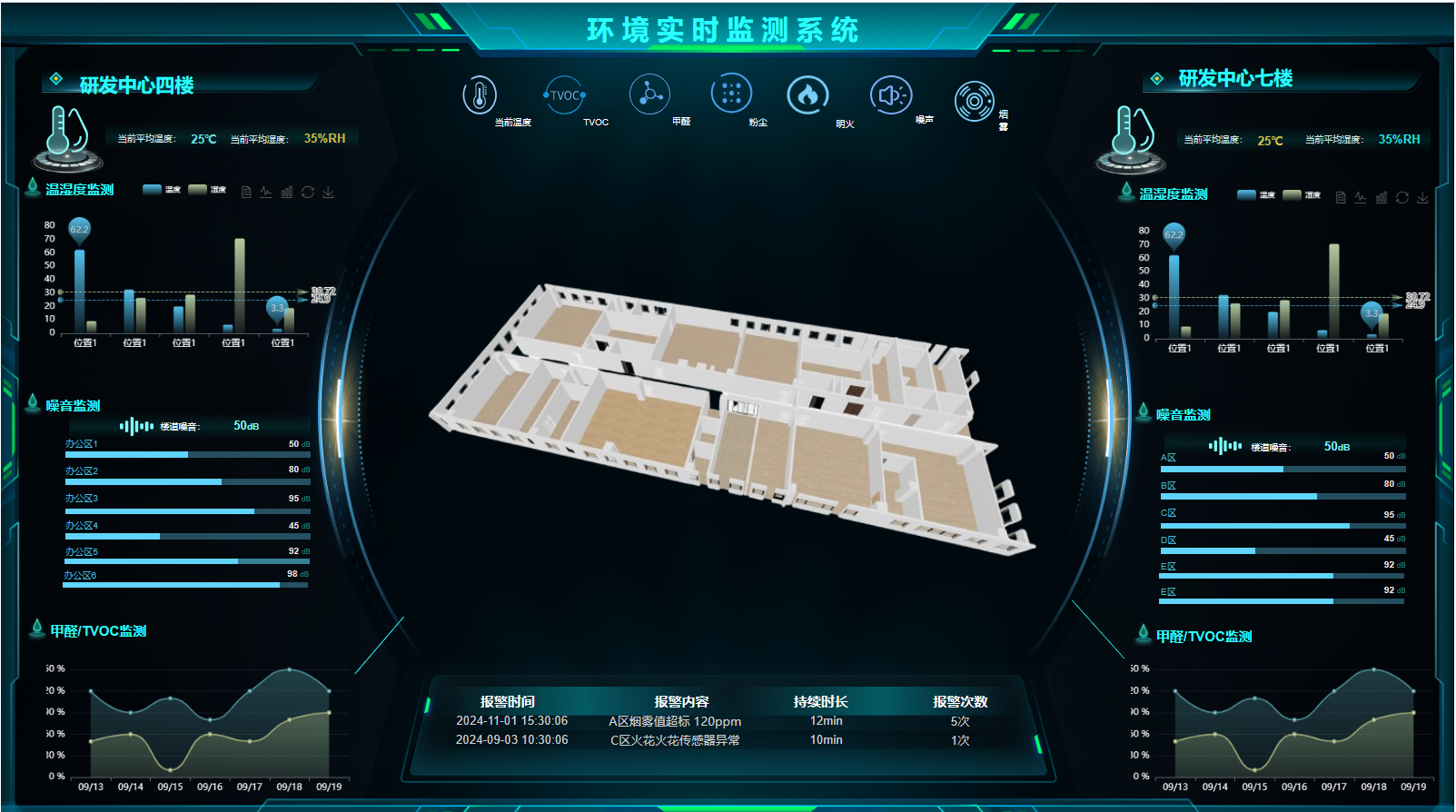

Key Features of the Safety Real-Time Monitoring System

1. Real-time monitoring of various environmental conditions, including dust (e.g., PM2.5 and PM10) and the concentration of toxic gases such as formaldehyde. 2. Immediate alarms when values exceed the standard, notifying users of toxic gas over-limit situations. 3. Detailed alarm information, including alarm location, range values, exceeded micro-values, alarm time, and duration. 4. Alarm history records for tracking past incidents. 5. View 24-hour trend charts to analyse environmental change.

What Problems Does the Environmental Routine and Real-Time Monitoring System Solve?

1. It enables continuous and stable monitoring of environmental pollution progress. 2. It provides environmental data analysis models. 3. It achieves early warning and alarm functions. 4. It allows staff to promptly view the factory production environment status and take targeted measures in a timely manner to prevent and maintain environmental pollution.

Application Scenarios

Application scenarios

Intelligent shelf IoT management system

The intelligent warehouse management system realizes the full cycle, scientific and standardized management of warehouse electrical control from purchase and storage, shelving, material requisition, maintenance, etc. The R&D system is based on IoT technology and adopts advanced technologies such as ZIGBEE communication technology, new sensing technology, and big data analysis, combined with RF tags and software operating system, rich and detailed interface display, query prompt alarm and other functions.

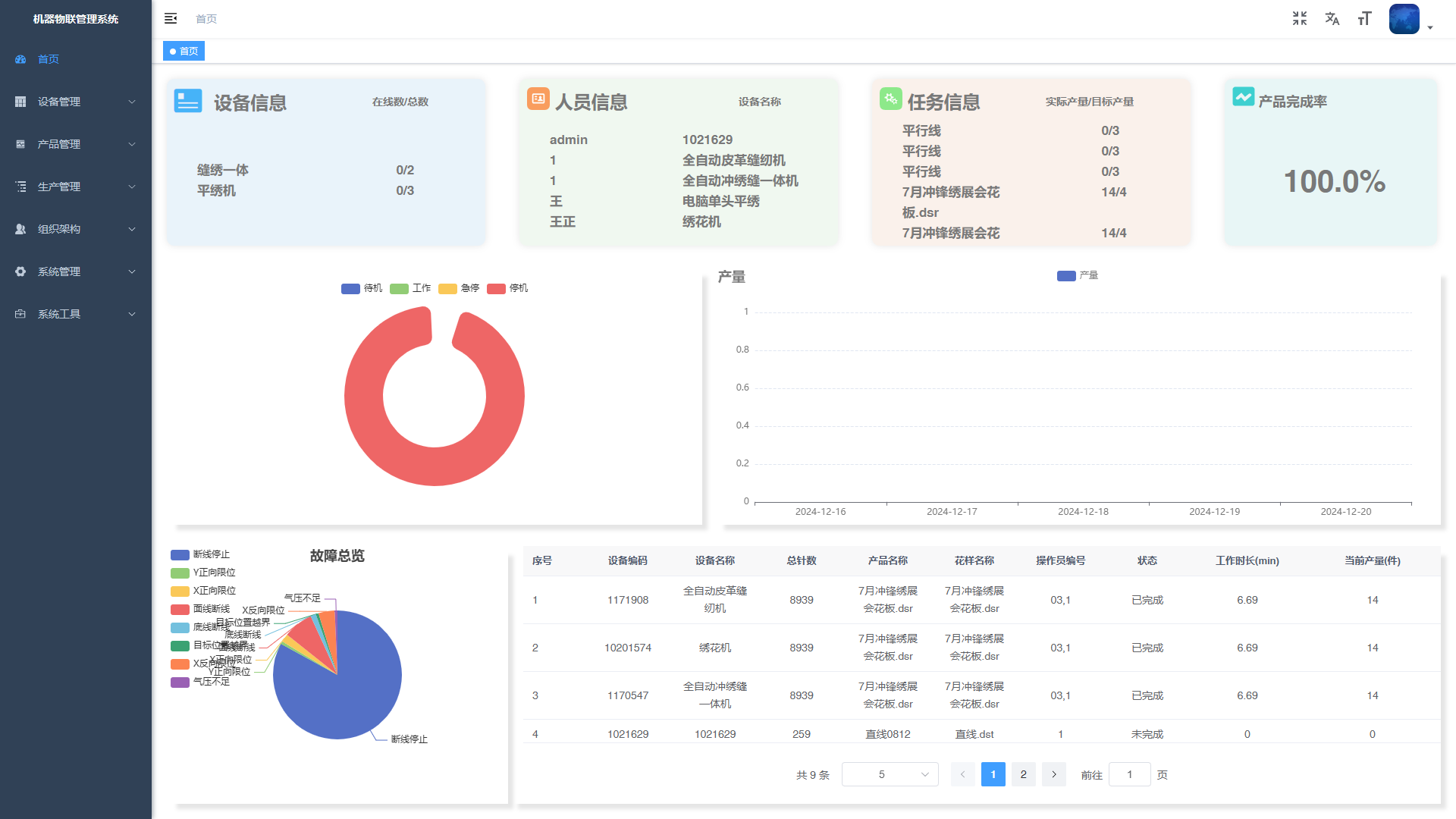

Machine IoT Management System

Machine IoT management system is a system that utilizes IoT technology to monitor and manage equipment production. This includes functions such as device access, data collection, issuing work orders, fault warning, and data analysis to improve the operational efficiency and intelligence level of the equipment. Thus promoting the improvement of production efficiency, product quality, and business model innovation.

Working condition enterprise equipment monitoring center

The working condition enterprise equipment monitoring center is committed to providing comprehensive equipment status monitoring and management solutions through advanced data analysis and real-time monitoring technology. Being able to record and analyze the status changes, real-time current consumption, and cumulative power consumption of equipment within 24 hours, helping enterprises comprehensively understand the key indicators of equipment operation. By statistically analyzing the frequency of alarm information, the monitoring system can deeply reveal the usage of equipment at different time periods, accurately distinguish between planned and actual production time, and timely identify and control unplanned production downtime. Through this system, enterprises can achieve intelligent equipment management, reduce failure rates and downtime, thereby improving overall production efficiency.