GetonAgain Garment CAD V2024.1

Applicable to clothing, underwear, shoes and hats, bags, sofas, tents and other industries

.png)

Software Features

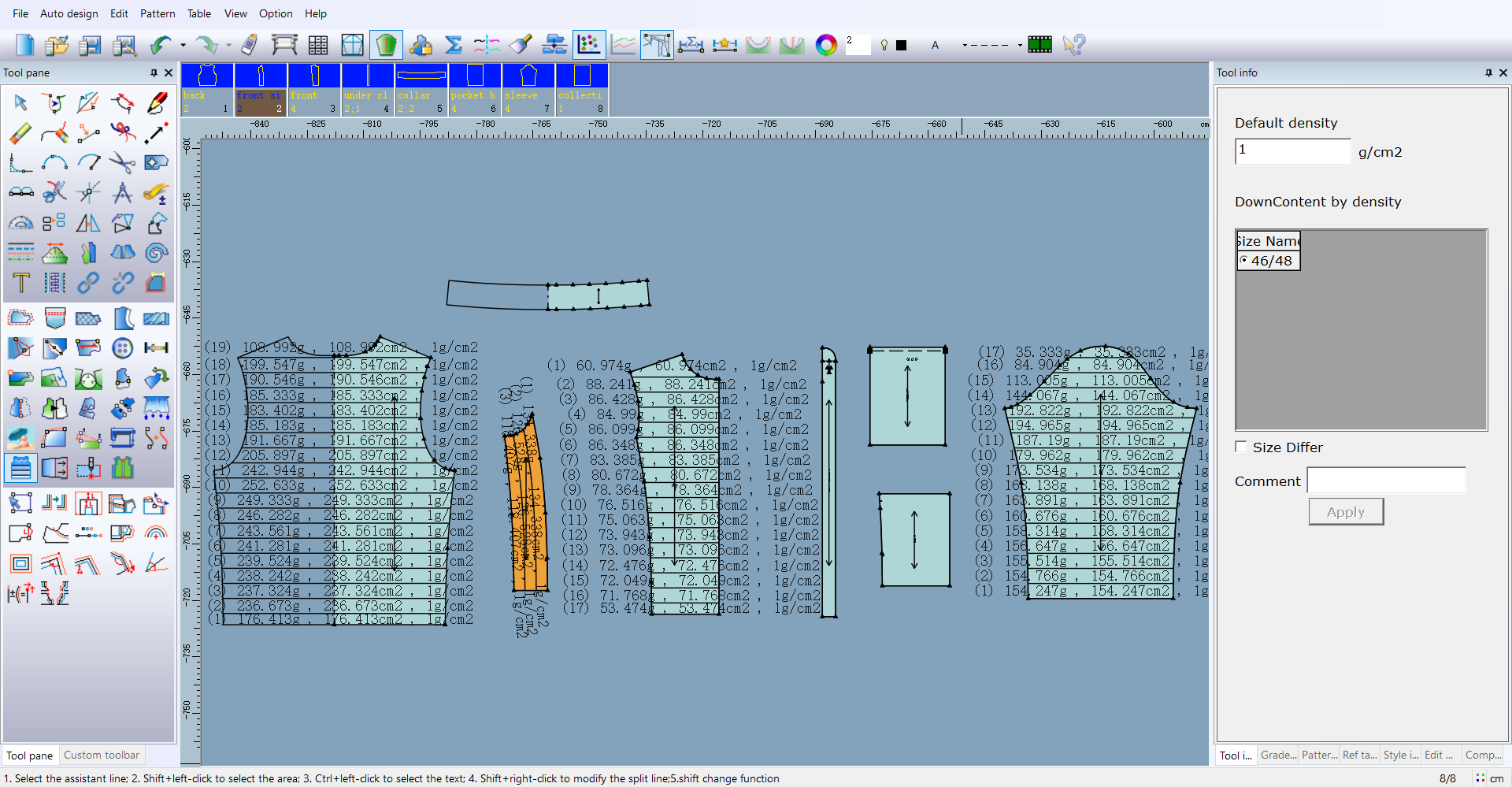

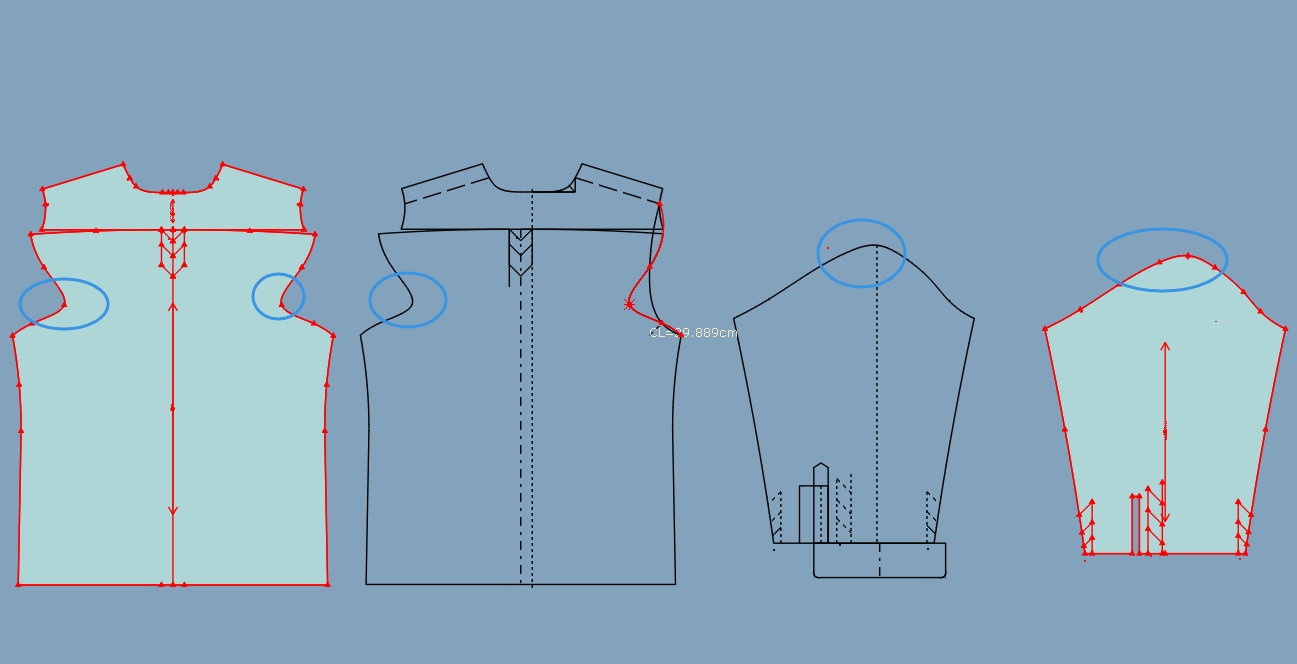

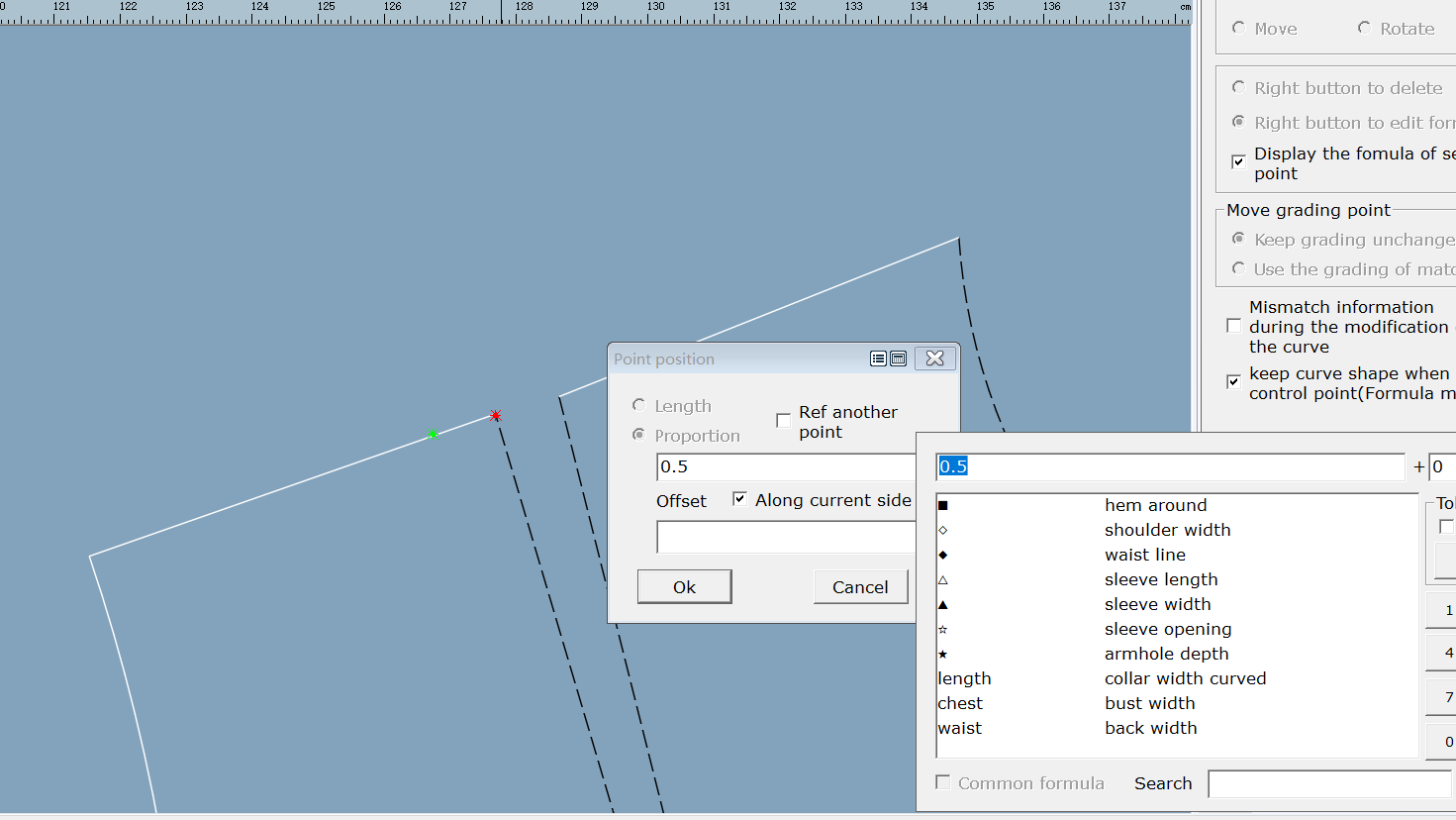

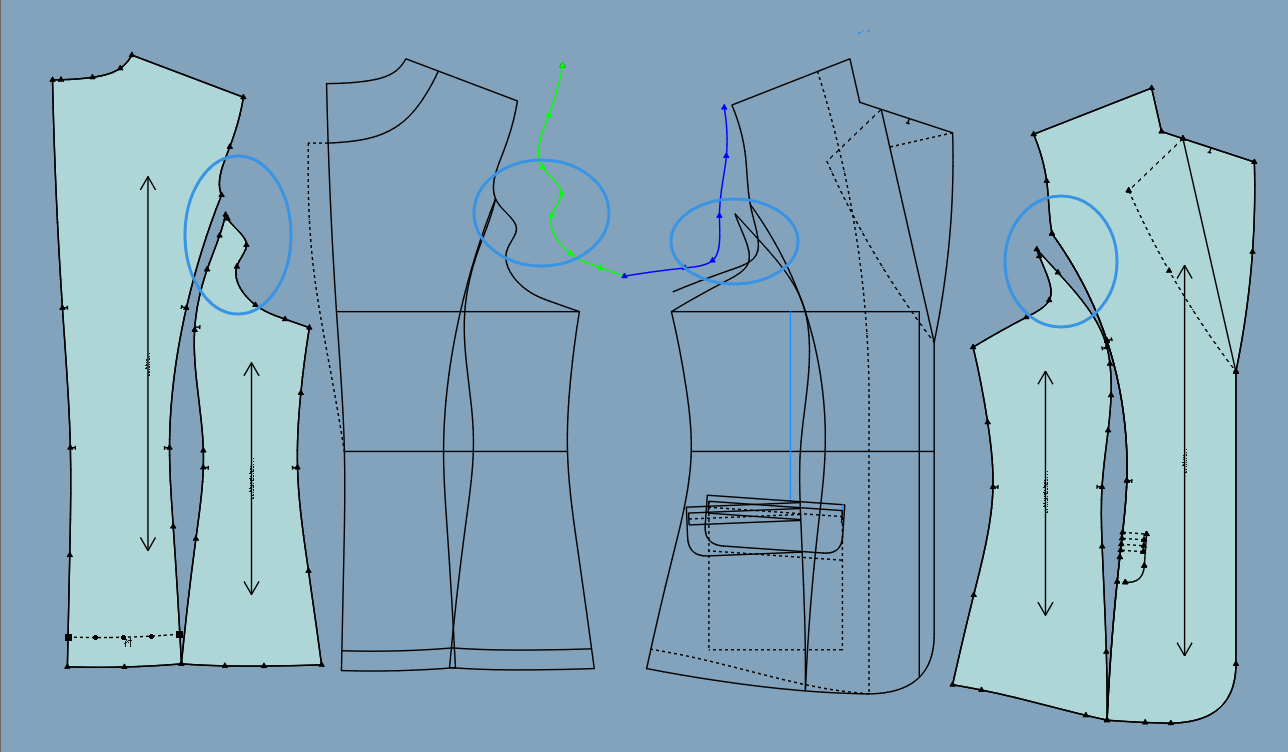

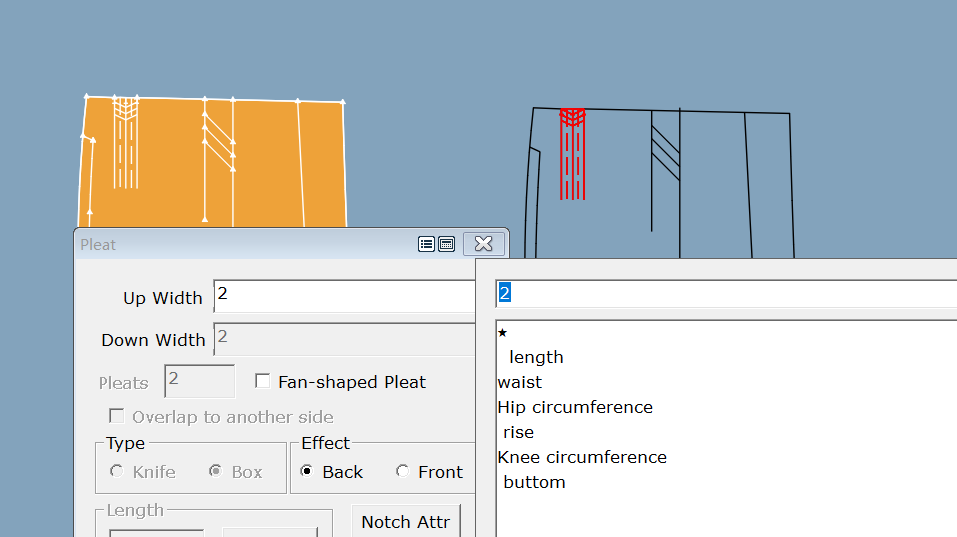

1 The system pattern making and grading adopts a new design idea, which integrates the formula method and the free method. One part, other related parts are modified together, and elements such as notches, buttonholes, drilling, darts, and pleats can also be linked.

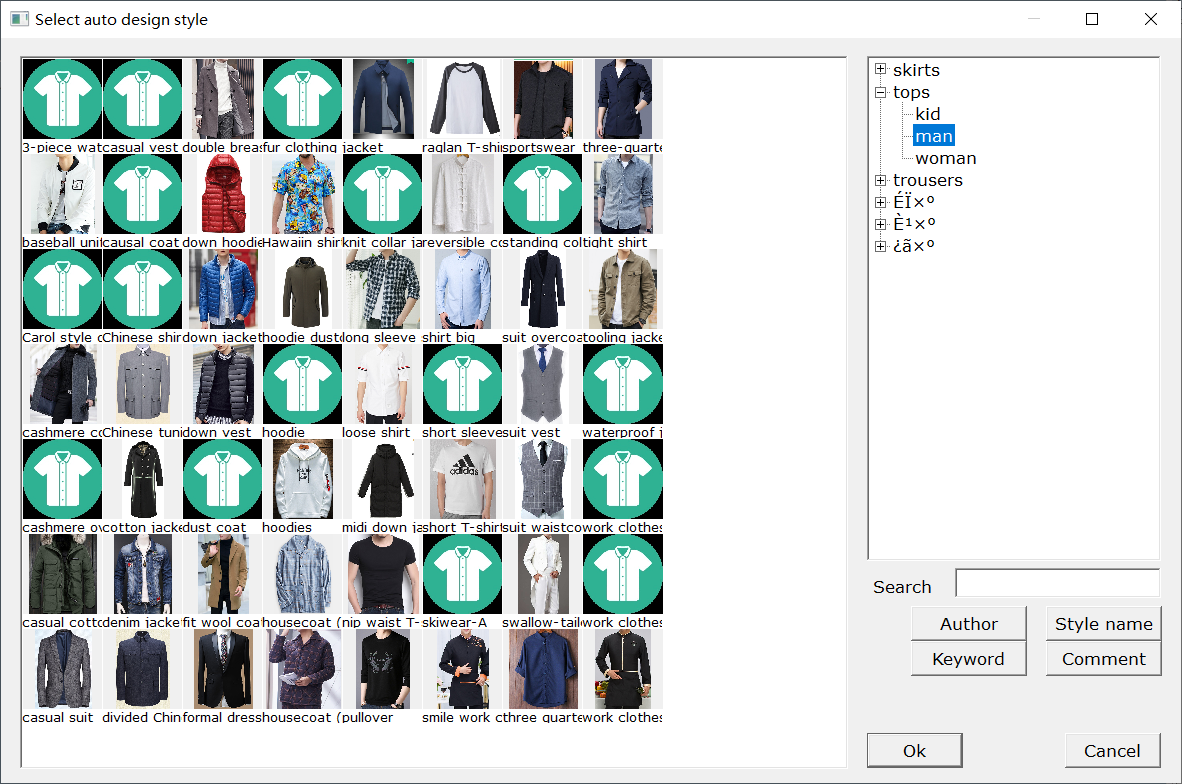

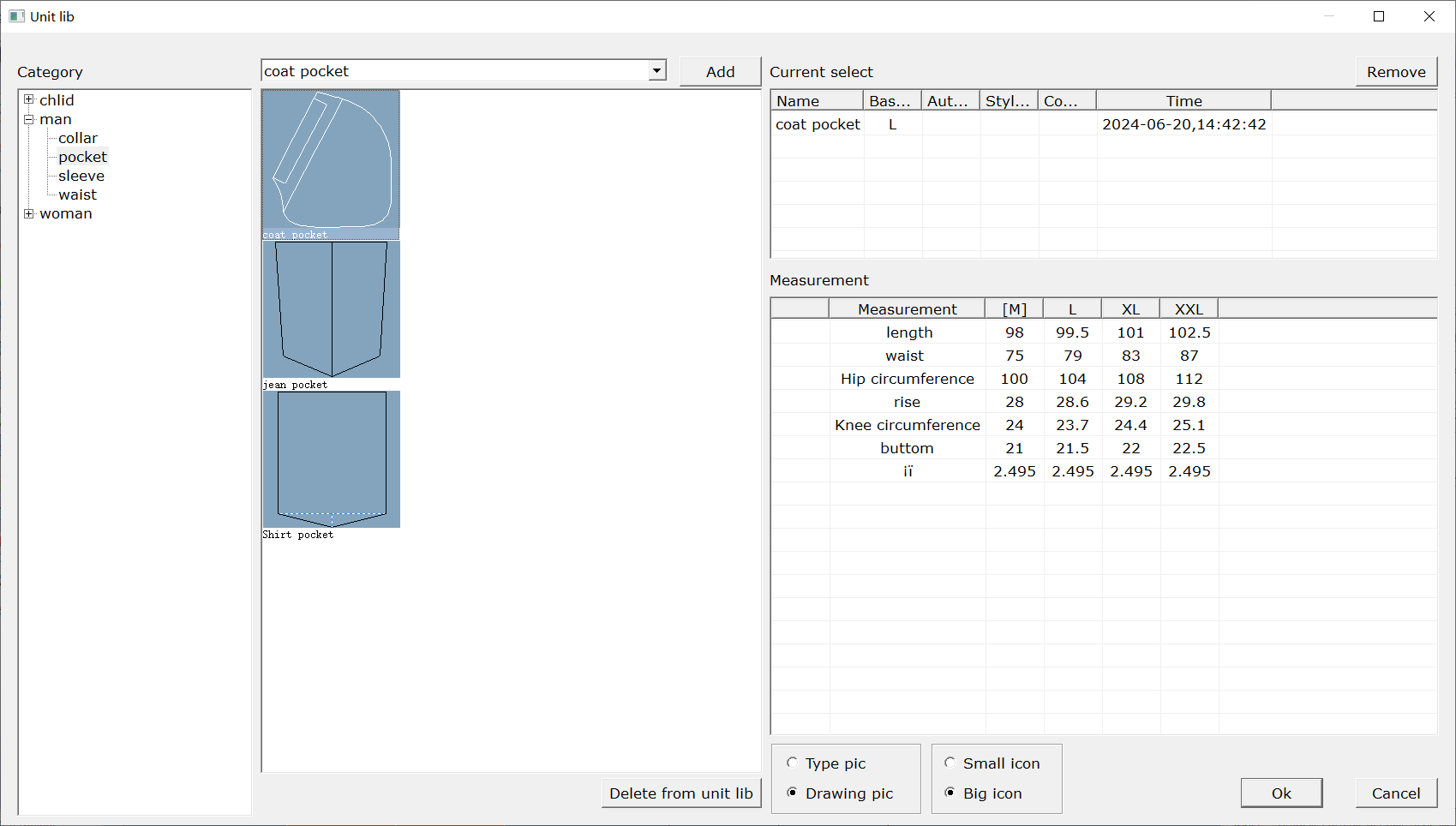

2 Design line linkage, the design line is linked with the pattern - the triangle point represents the linkage point.

3 Link to province - you can continue to change the distance or ratio after you switch to province.

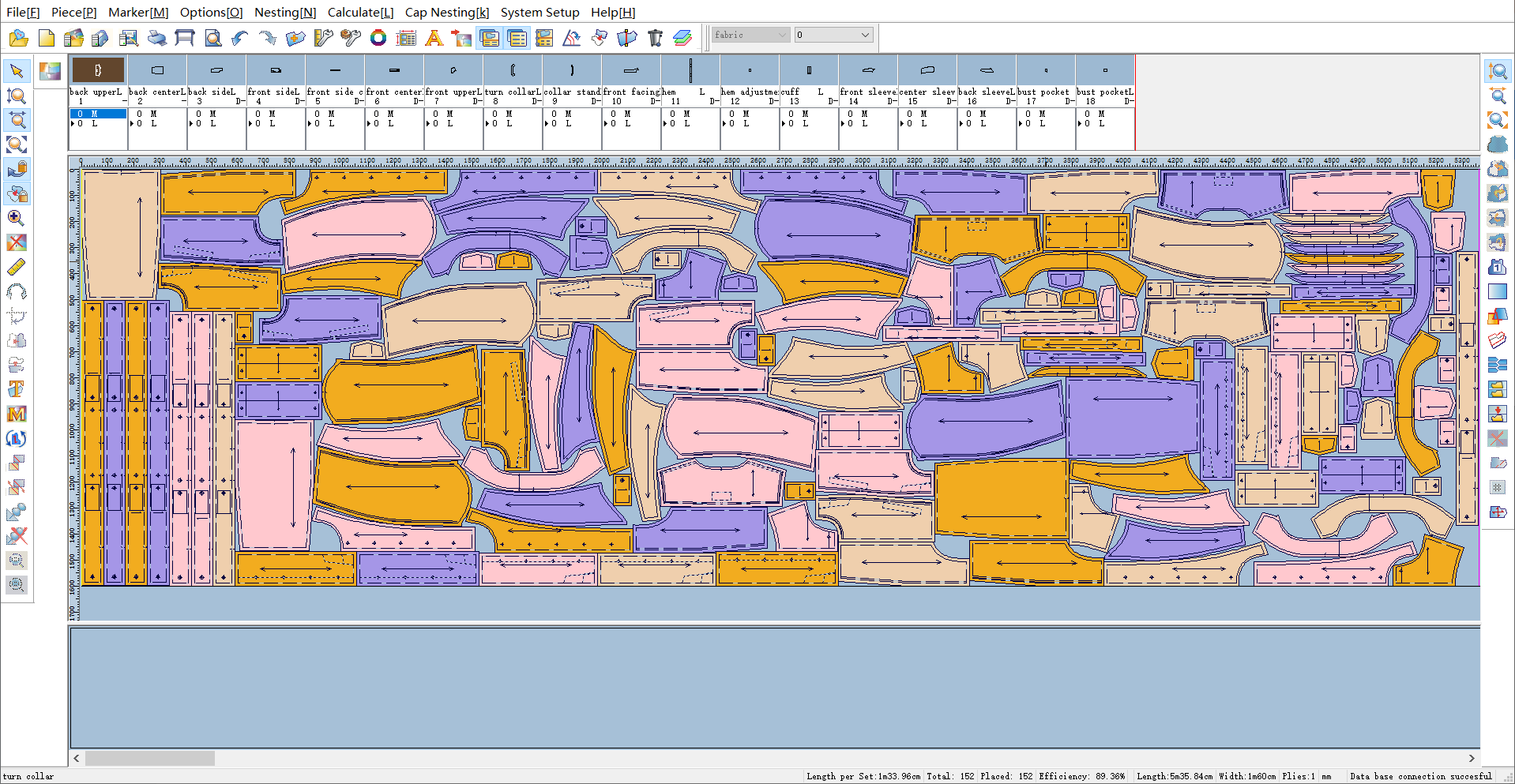

4 Merge adjustment linkage.

5 The plate-making and grading part retains the original garment CAD functions, which can be added, converted, pleated, etc., provide a wealth of seam allowance types, process identification, can customize various line types, and allow users to build parts libraries, such as The collar, cuffs and other parts are directly loaded when using.

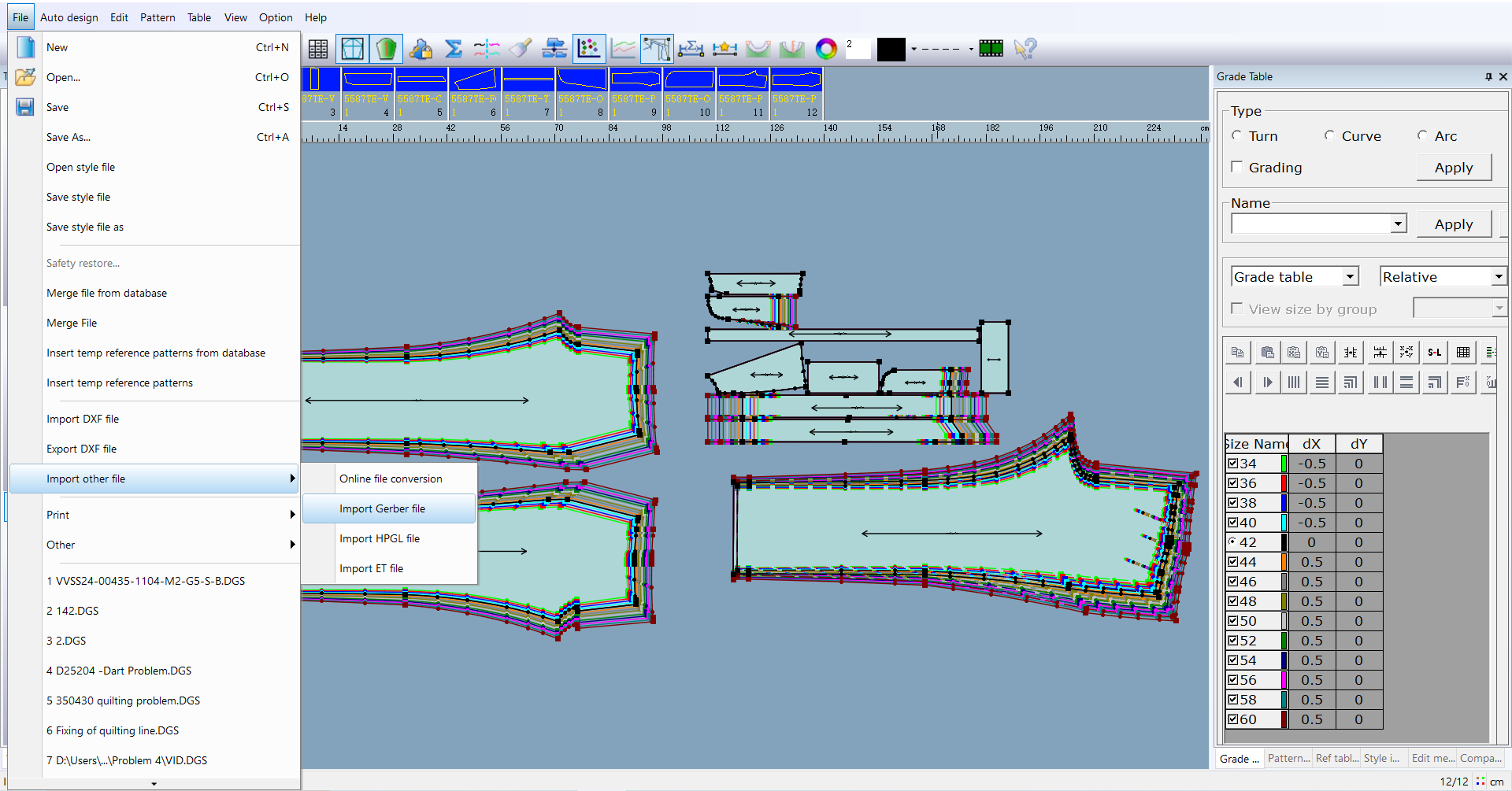

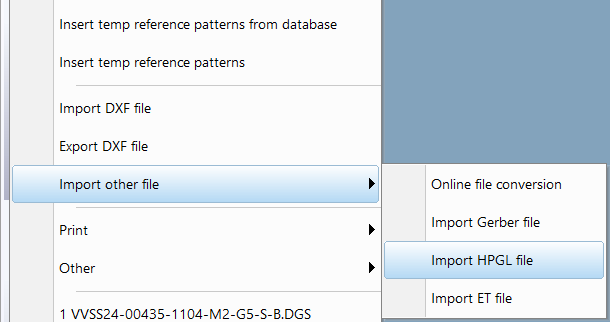

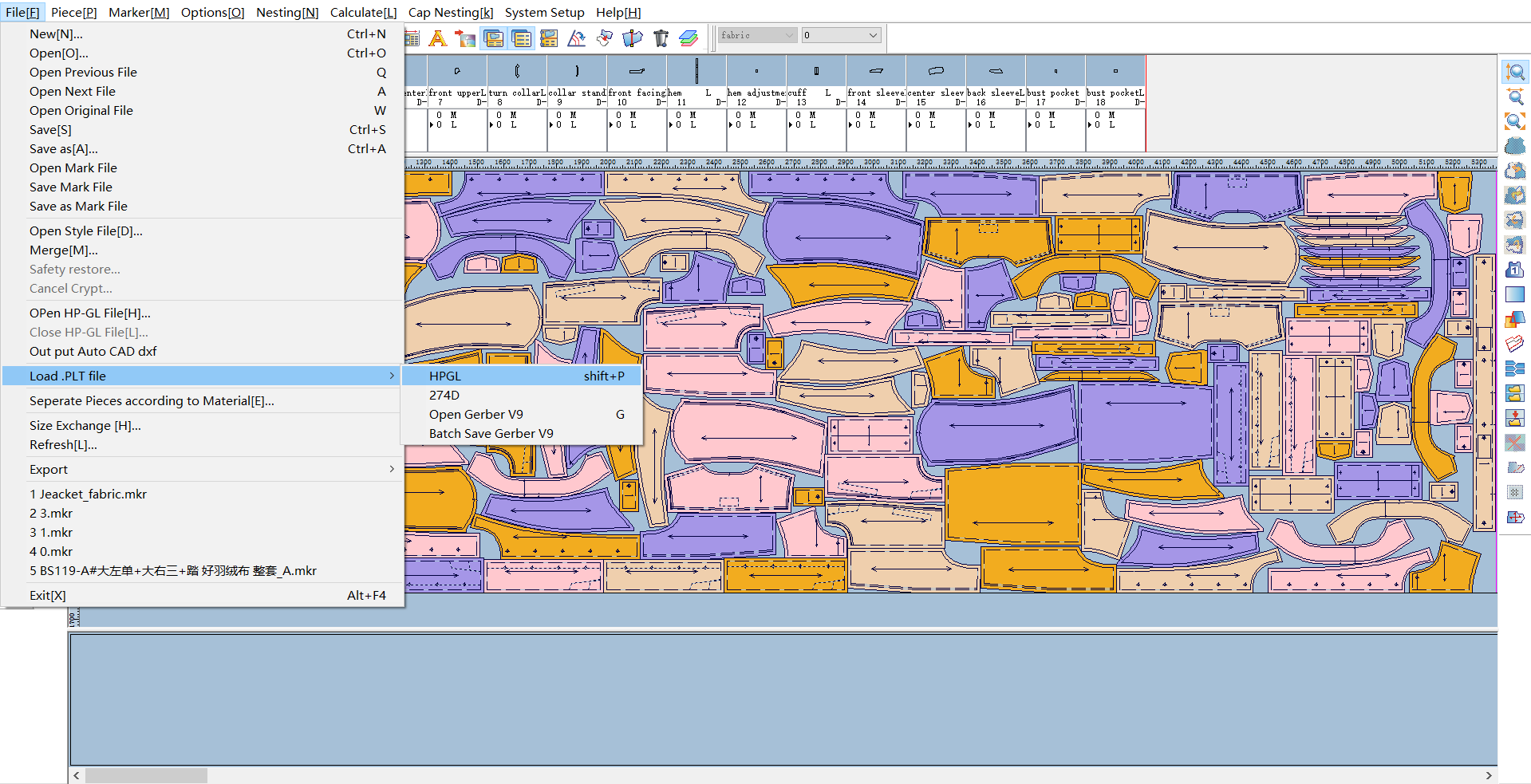

6 Import files in various other formats, such as DXF(AAMA/ASTM/AUTOCAD)\PLT\ZIP\MODEL.

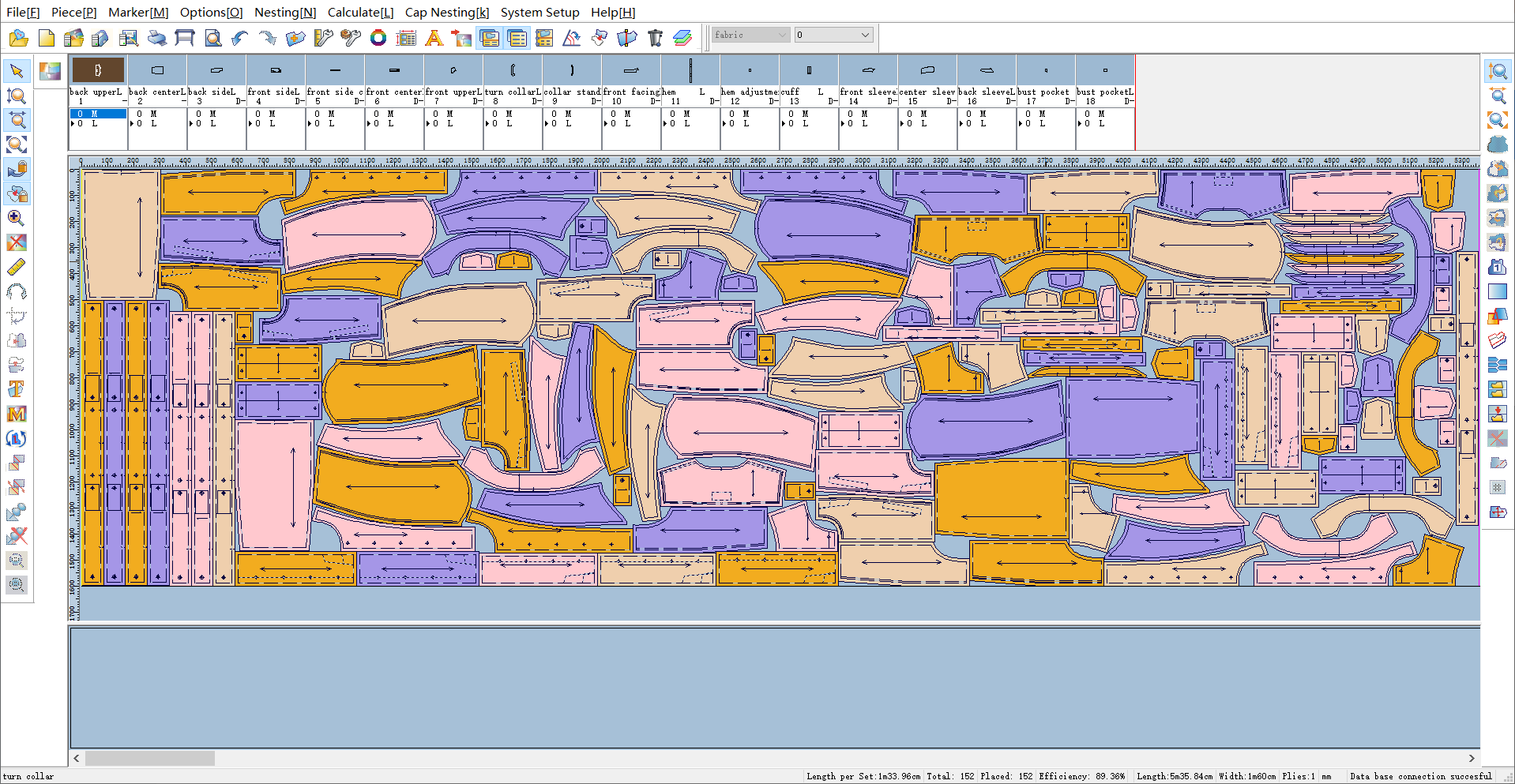

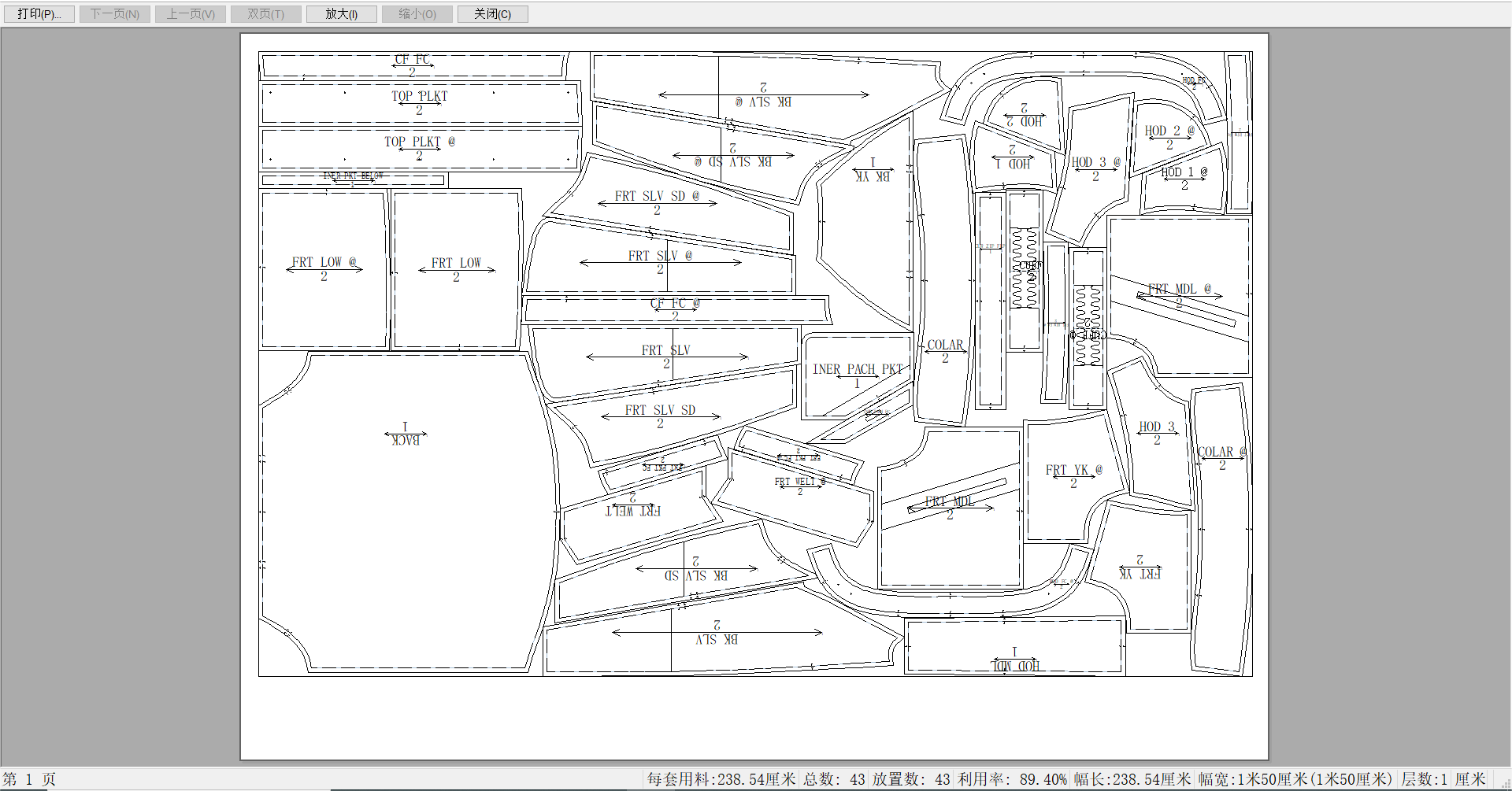

7 GMS can read design grading system files, dual interface can nest together. Providing Supernest,Automatic, manual and interactive, and other various nesting ways. Among of them, supernest is international innovative technology. System can automatically finish one lay of marker in a very short period, the fabric utilization can be or even higher than the manual nesting. Specially prevent the horizontal & vertical shading,and mixed shading problem. It is possible to process multiple marker jobs in queue. Save time and improve productivity. Manual nesting, flexible sloping the patterns, fine-tuning and good utilization of fabrics. The system supports nesting and cutting of the inner contours, connecting with output devices, printing small samples, drawing and cutting 1:1 patterns.

8 GMS tailor-made cap function is used to toys, gloves, underwear, etc. Copy, inverted truss function to achieve a high utilization of the fabric. GMS can read various HPGL files successfully, import theHPGL\PLT\CUT\Gerner files and re-nesting.

9 GMS can be expected to quickly calculate the amount of cloth used and the number of pieces to be cut,increase production efficiency, increase control over the market, and save time and money! The system supports nesting and cutting of the inner contours, connecting with output devices, printing small samples, drawing and cutting 1:1 patterns.

Related Products