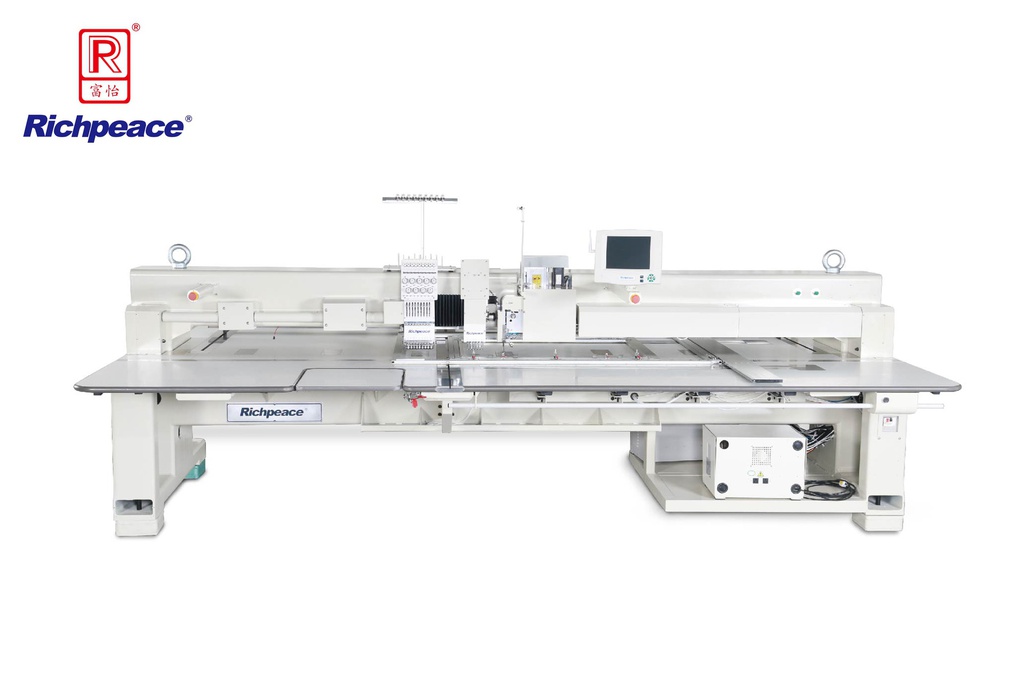

1. Machine sewing area: 900 x 600mm (other sewing area can be customized).

2. Spindle drive and sewing frame drive are driven by servo motor, independently controlled.

3. Independent research and development of electro-mechanics to meet customer's customization function.

4. Independently developed intelligent punching and embroidery sewing layout software, which is conducive to one-time forming.

5. Bridge type structure, stable frame, large sewing area, can make any pattern designs.

6. Equipped with automatic vacuum cleaning equipment to remove the scurf.

7. Automatic oil supply system, improve the life of the equipment, reduce manual maintenance.

8. Sewing with 2X jumbo rotary hook, embroidery head using standard rotary hook, those are original Japanese brand.

9. Sewing head can be automatically lifted to prevent collision of the frame, and thread off.

10. Special multi-function frame, can meet the processing of different thickness leather and composite leather.