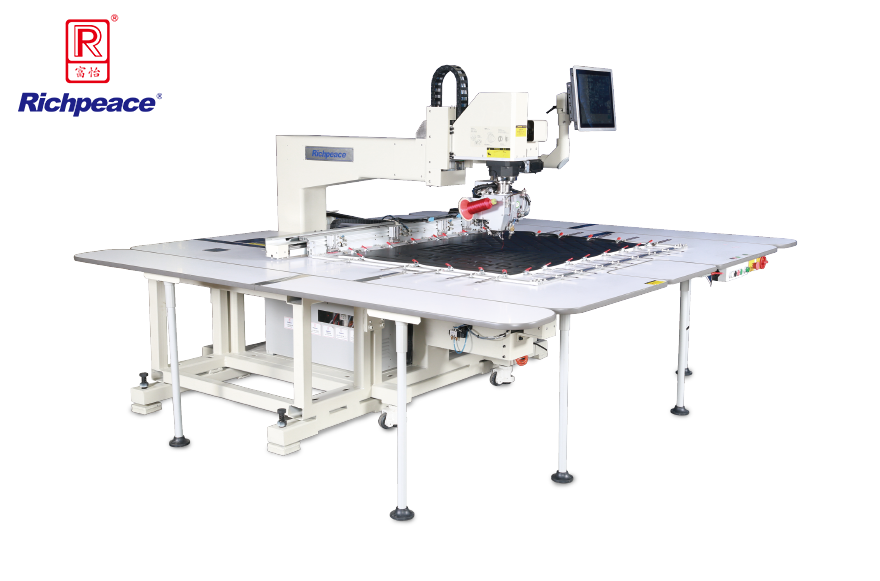

1. Richpeace sewing electronic control system, ARM core + LINUX system.

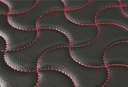

2. The independently driven 360° rotary head is adopted to avoid the difference in the quality of the positive and negative stitches.

3. Machine head is pneumatically lifted, lifting stroke: 50mm, which is convenient for changing the material frame, which is conducive to step sewing, and the equipment is safer.

4. Driven by imported servo motors and driven by high-precision linear guide rails to ensure accurate patterns.

5. The needle bar and hook shaft are treated with DLC diamond-like coating, which is wear-resistant and can work normally at high speed without oil or with little oil.

6. 15-inch high-definition industrial flat panel, easy to operate.

7. With automatic pneumatic thread trimming, upper thread breakage detection, bobbin thread counting functions, and tooling template in-position detection functions.

8. The table support structure is adopted to ensure the flatness and accuracy of the product under machine high-speed operation.

9. Equipped with Richpeace sewing CAD software, the pattern can be arbitrarily designed, easy to learn.

10. SMC atomized oil injection to realize automatic lubrication of main transmission components.

11. Insert the USB Drive into the USB port for pattern import, and the stitch file capacity is large enough.