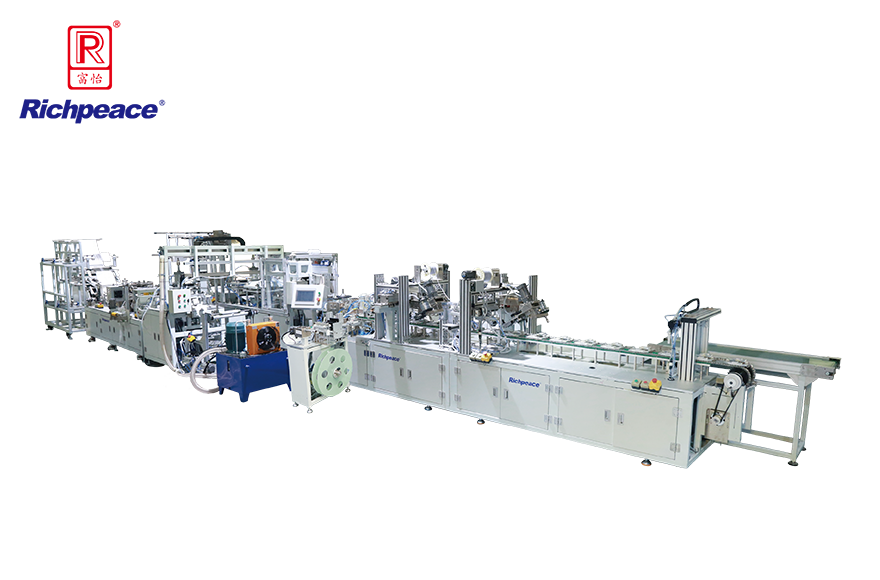

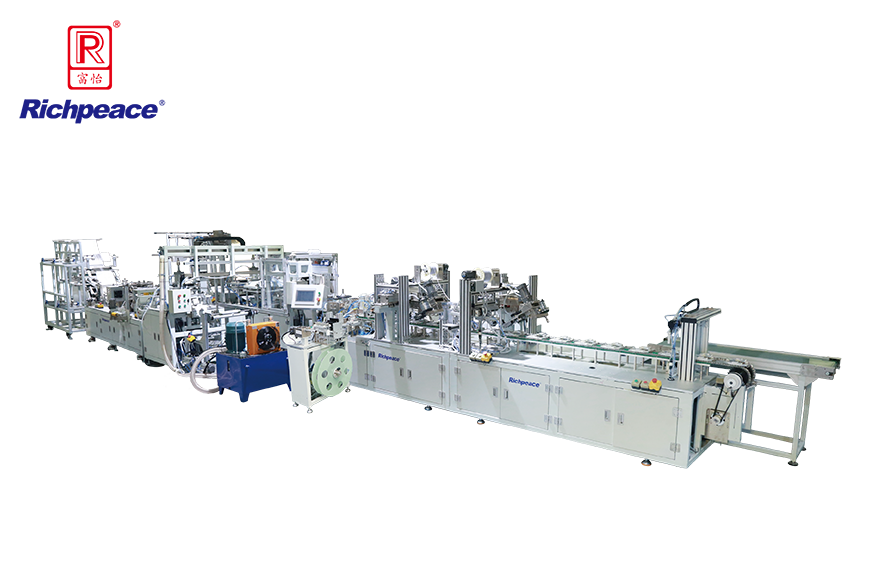

1. Fully automatic production line includes raw material feeding, cup forming, filter layer pre-forming, edge sealing and cutting, transferring to pad printing, sponge strip sticking, automatic external nose clip, headband stapling (optional headband welding), ultrasonic breath valve welding (optional), Manipulator grab and mask transmission.

2. The filter layer pre-forming function adopts separate forming design to better ensure that the melt blown non woven fabric and the protective layer fabric are evenly distributed, and the filter performance of the melt blown non woven fabric and the fabric is completely retained.

3. Automatic nose sponge strip sticking, labor saving.

4. Automatic pad printing device, high efficiency with clear pattern.

5. Constant temperature sensor automatically attaches the external nose clip, the cutting is smooth & firmly fixed.

6. Automatic double sides headband stapling device, the length is adjustable, strong for pulling.

7. Finished Mask and scrap are separated automatically.