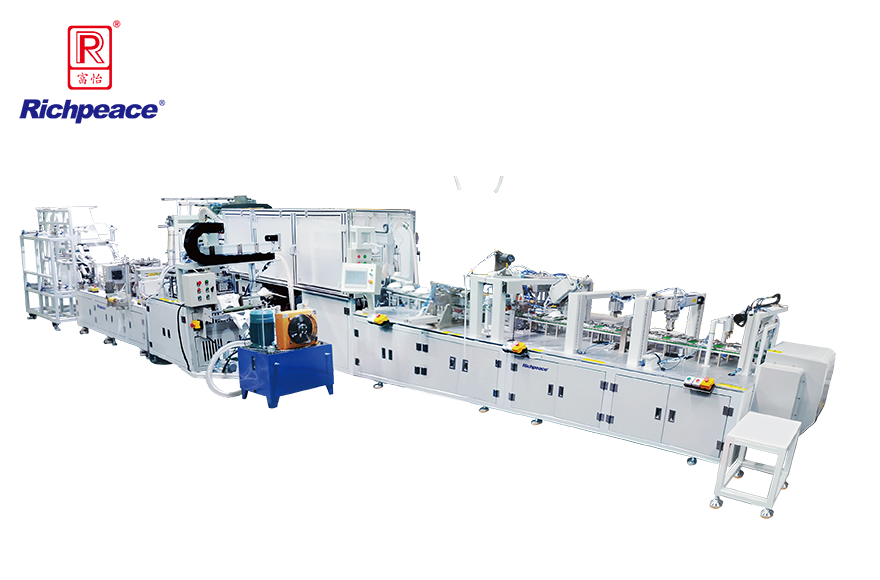

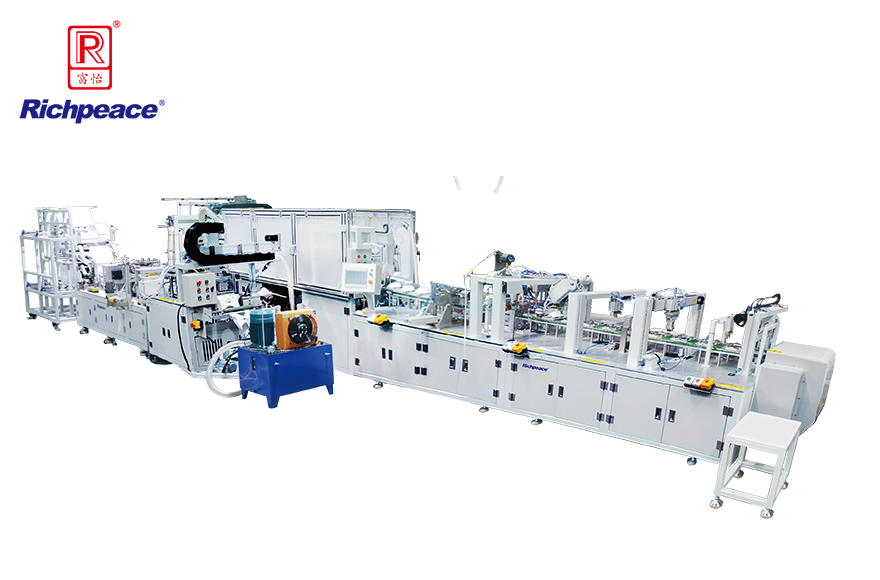

1. Integrated design, from feeding raw materials to cup forming, filter fabric pre-forming, cup border welding & cutting, automatic transferring to outer nose clip, pad printing, headband coiling, automatic ultrasonic breathing valve welding (optional), manipulator grab and automatic convey, etc. One station of automatic cup type mask production.

2. The filter layer pre-forming function adopts separate forming design to better ensure that the melt blown non woven fabric and the protective layer fabric are evenly distributed, and the filter performance of the melt blown non woven fabric and the fabric is completely retained.

3. Automatic pad printing device, high efficiency with clear pattern.

4. Automatic headband coiling device, manual locking to adjust the tension, easy to operate.

5. Mask and scrap are separated automatically.