1. Automatic computer program control, replacing the manual sewing mode of one person and one machine;

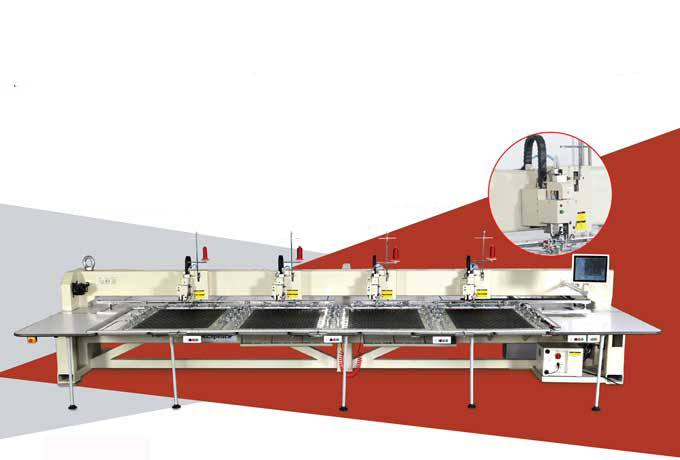

2. The four heads work at the same time, the sewing efficiency is four times that of ordinary machines, and mass production is efficient;

3. The machine head can work independently, and select any one of the machine heads to work or stop through the control panel;

4. The pneumatic lifting of the machine head makes it easier to replace the template, which is suitable for sewing a variety of thick materials;

5. The stitching standards are the same, and the special sewing process is easily realized;

6. The sewing pattern can be freely designed, and the control system can identify the technical requirements of the product such as lock needle, needle size, and encryption needle in the design file;

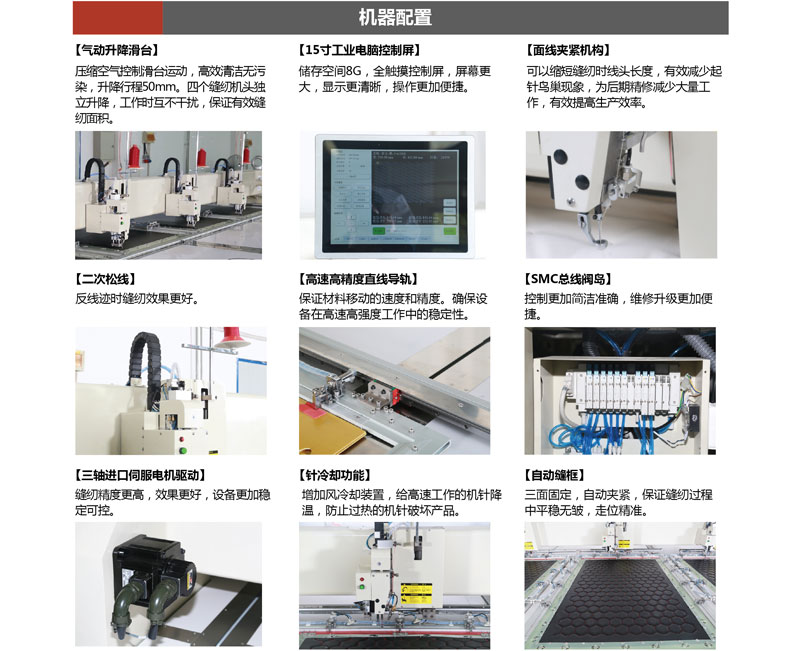

7. Upper thread clamping mechanism: It can shorten the length of the thread at the time of sewing, effectively reduce the phenomenon of needle nesting, reduce a lot of work for later finishing, and effectively improve production efficiency;

8. Secondary loose line: the sewing effect is better when the stitch is reversed;

9. Three-axis imported servo motor drive: higher sewing precision, better effect, more stable and controllable equipment;

10. Needle cooling function: increase the air cooling device, cool the needle for high speed operation, prevent the overheated needle from damaging the product;

11. Automatic seam frame: fixed on three sides, automatic clamping, ensuring smooth and wrinkle-free sewing process and precise positioning.