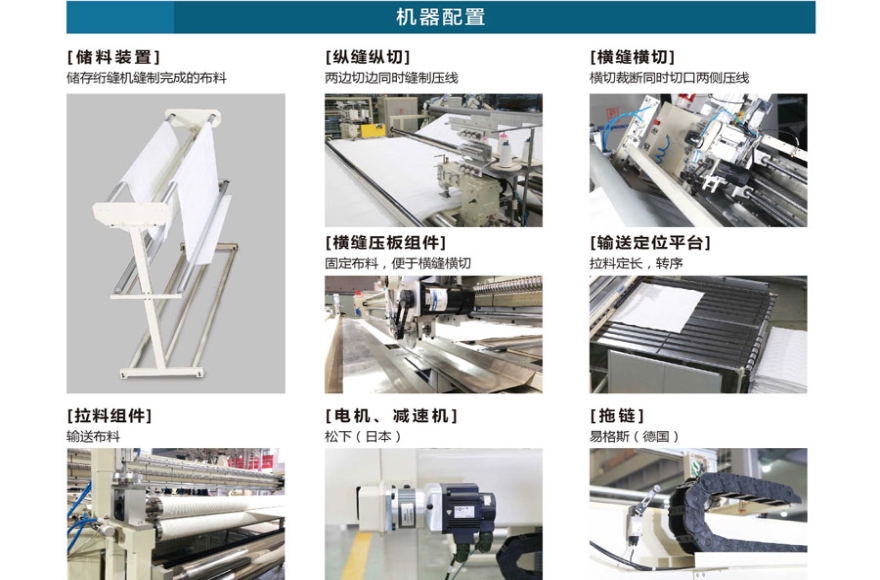

Features:

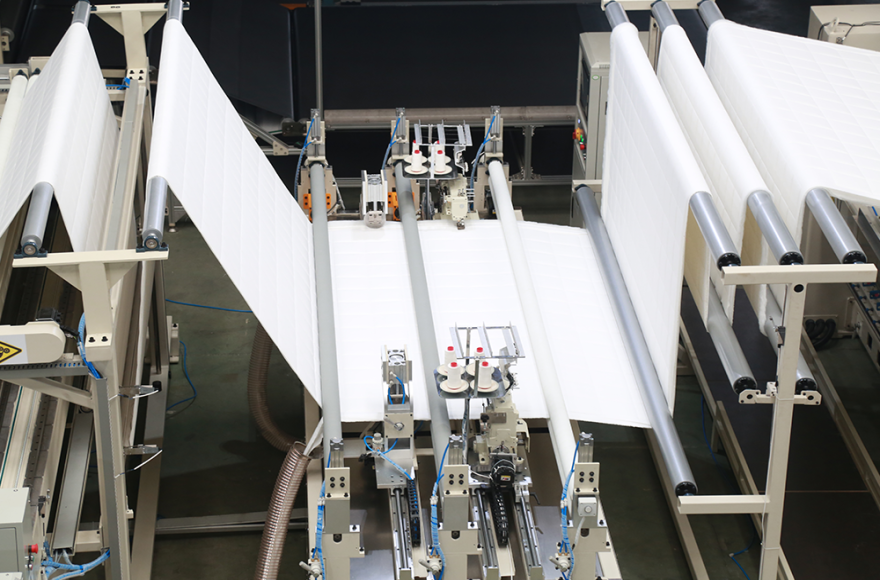

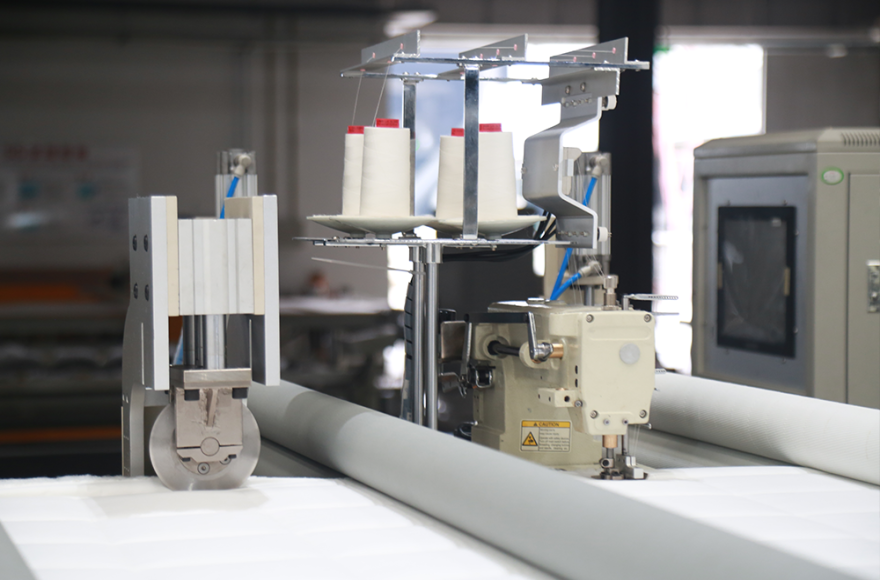

1. Longitudinal sewing: two lines chainstitch (optional lockstitch or overlock stitch).

2. Cross sewing: multi-needle chainstitch sewing.

3.Full servo motor control system, providing strong and accurate driving power.

4. With scrap collection device to keep the workshop clean.

Application:

1. Turnover Quilt Technology

For comforter case 4 side sewing with fabric and fiber filling, while keep one side with open gap in order to turn over the case.

Main features:

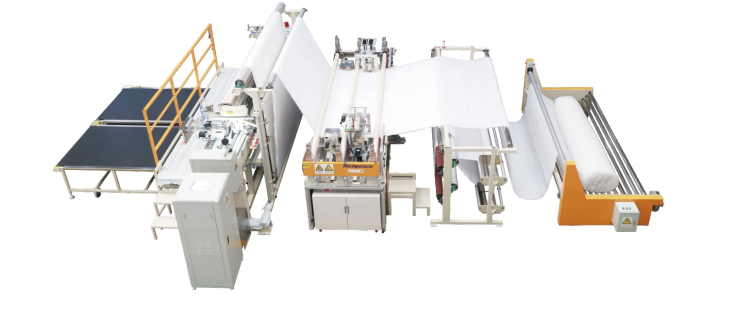

(1)Integrated multiple processes in one production line: including fiber feeding, comforter case 4 side edge sewing,cutting.

(2)Visual positioning technology makes open gap position more accurate.

(3)Open position and size could be freely adjusted.

(4)Small floor space, strong compatibility, could be working standalone or connecting to other production line.

2. 4-Side Hemming Sewing

Main features:

(1)Make 4-side edge hemming and panel cutting process after quilting process, easier for the afterwards edge tape binding.

(2)Solved thread bursting issue of the cutting edge after quilting, reduced the difficulty of heavy material binding, and improved binding quality.

3. Automatic Production Line for Multi-needle Pattern Comforters with Tape Binding Edge Finishing

Connecting with GetonAgain L2000 high speed multi-needle quilting machine and automatic tape binding machine. Realized fully automatic production line for multi-needle quilting pattern comforter with tape binding edge finishing.