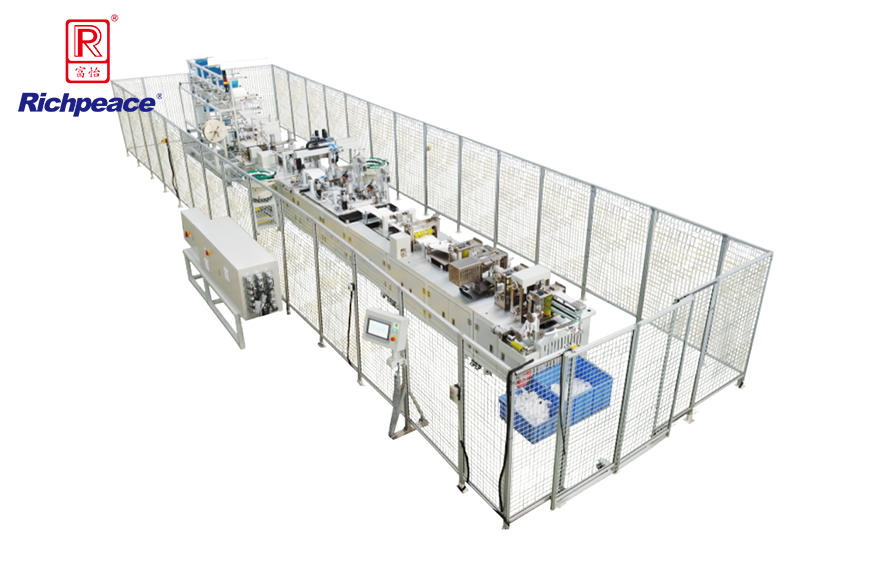

Foldable Mask Production Line-UL Certified

此产品已停产。

Model:

RPFM-A-C-S-FI-RI-UI2-UH1-SS1-1BC-3P380

主要技术结构:全自动折叠口罩生产线主要由十二个部分组成:上料架、上内置鼻梁条、压花焊接、喷印装置、上呼吸阀、头带焊接、上海绵条、材料对折、封口焊接、口罩套切、下料导出、废料收集装置组成,实现折叠口罩自动化生产。

1. From raw materials to finished products, the production is done fully automatically, without human intervention, realizing automatic production of folding masks.

2. Every step and process in the whole production line are closely connected, and the max. Production speed is 28pcs/min. Under stable working condition.

3. Labor-saving, and mask quality in good consistency: the whole production line only needs one person to operate, which is free of skilled worker, improved production efficiency and mask quality.

4. Humanized control: all the moving parts and components in the whole production line are installed with safety guards to ensure operator safety at max. All faults have corresponding alarm information in the operation screen, which is convenient for supervision, maintenance and troubleshooting.

5. The whole production line is designed and manufactured according to the U.S. UL safety standards, including the U.S. Standard voltage input, separate wiring for high-voltage and low-voltage inside power cabinet, and all electrical parts as per UL standards.

| Model | RPFM-A-C-S-FI-RI-UI2-UH1-SS1-1BC-3P380 |

| Speed | 28pcs/min |

| Size | 167mm×112mm |

| Power Supply | 3- phase 380V/50Hz |

| Power | 12kW |

| Installation Area | 12145mm×2500mm×2000mm(L×W×H) |