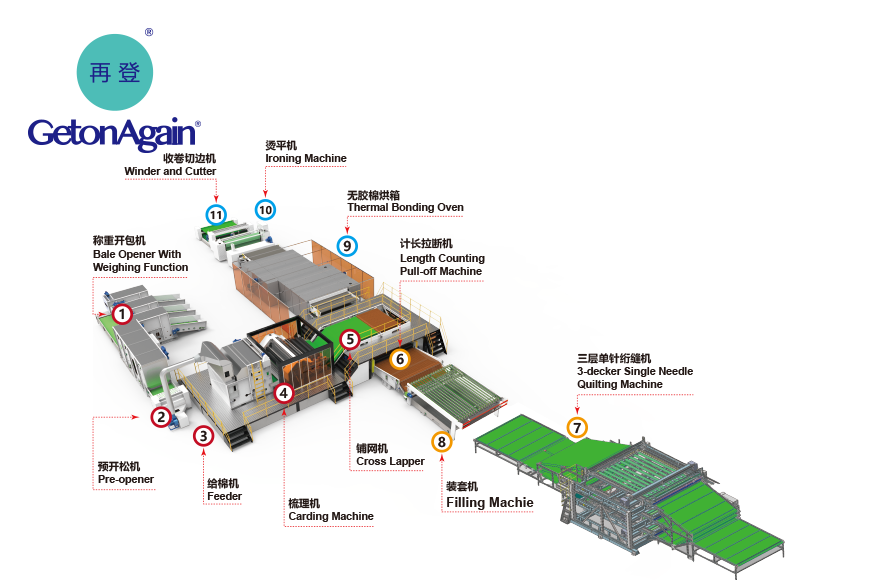

Single Needle Quilting Comforters Automatic Production Line

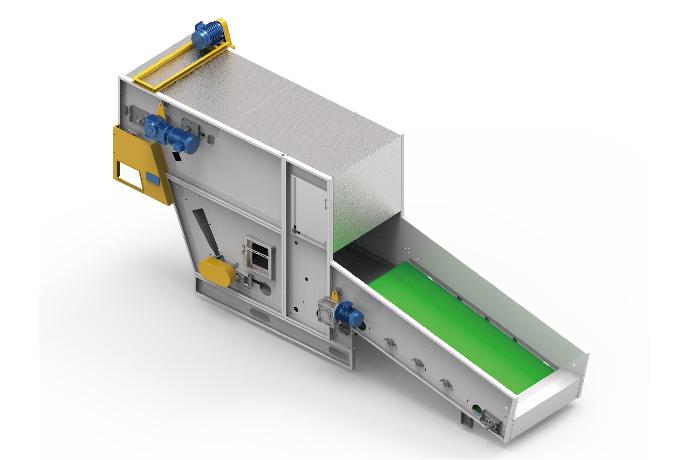

01 Bale Opener With Weighing Function

Transfer different specifications of bundled fibers to the next step feeding lattice at a set speed and proportion. Multiple sets could be used together.

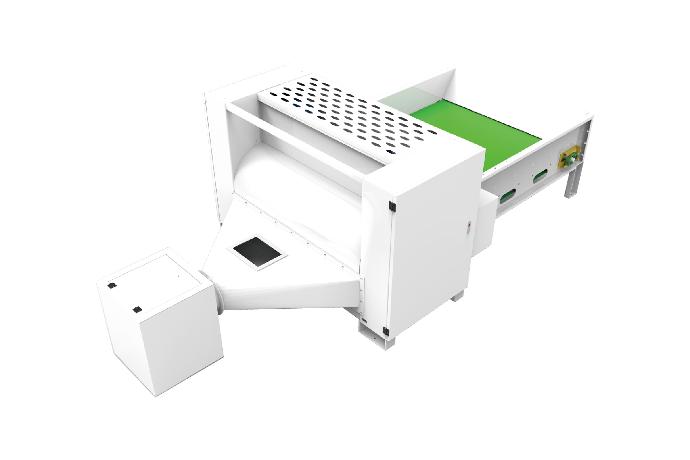

02 Pre-opener

Open and loose the raw fibers sent by the weighing bale opener and thensending to the feeder through blower; Standard configuration with cottonpressing device; The feeding length is related to the quantity of bale openers.

03 Feeder

Evenly feed the mixed fibers from bale opener into the carding machine.

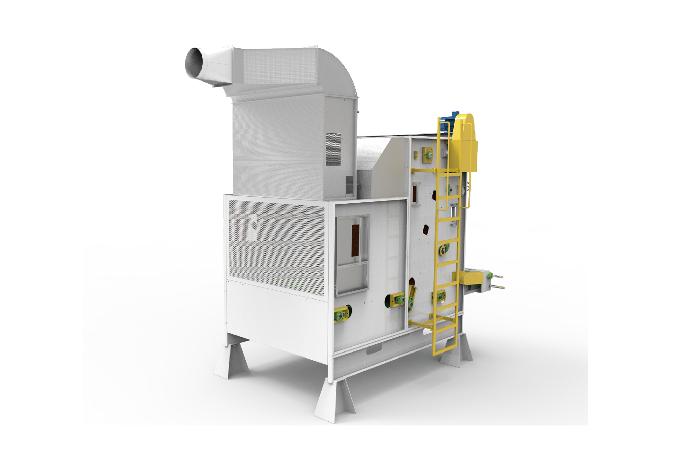

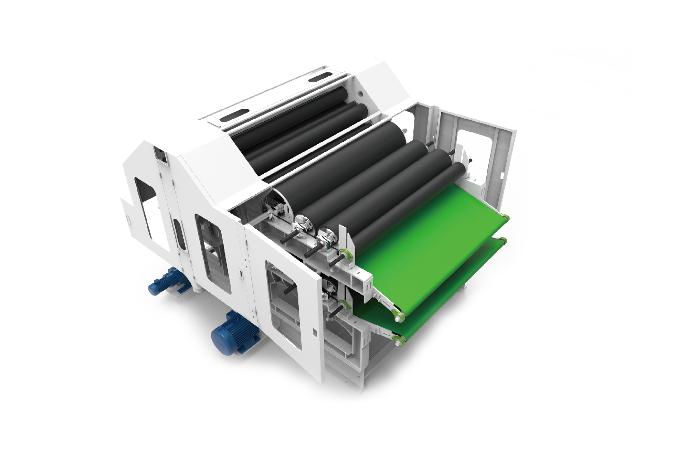

04 Carding Machine

Carding the fibers from feeder into webs and processing to quantitative fiber webscomposed of single fiber.

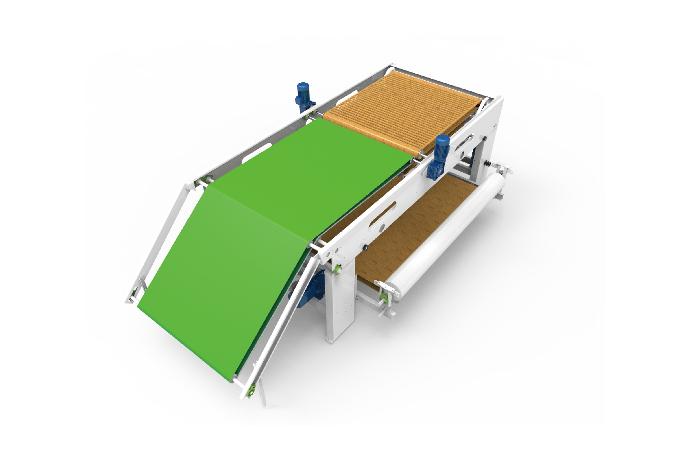

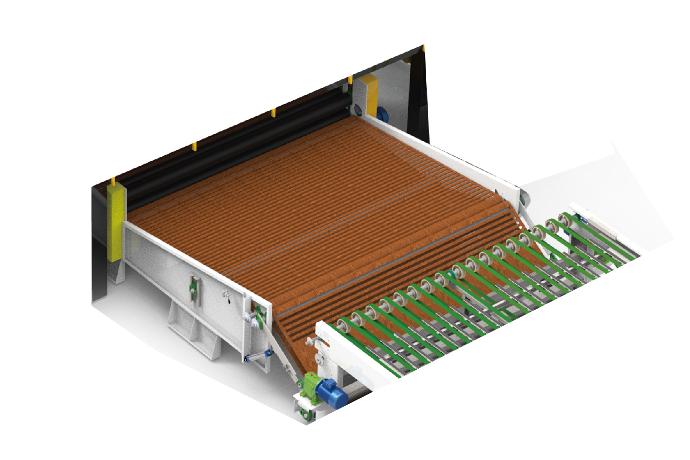

05 Cross Lapper

Evenly folding and lapping the fiber webs from carding machine to the setwidth and thickness and transferring to the next process.

06 Length Counting Pull-off Machine

Pull-off rollers have two sets rollers, the surface coated with rubber,electronic counting. When reaching the pulling-off length the motor will workautomatically.

07 3-Decker Single Head Quilting Machine

Suitable for single needle pattern used for comforter, sleeping bag, blanket, mattress cover etc.

08 Filling Machine

Automatically filling the fibers into the duvet cover after pull-off. Length set iscontrolled by computer and could set any value according to requirement.

09 Thermal Bonding Oven

Heating the laid fibers at hightemperature, so as to bond and fix the fibers well.

10 Ironing machine

To iron on the thermal bonded-wadding to make the surface flat and neat.

11 Winder and Cutter

Edge trimming, length counting, cutting and winding for silk-like cotton, thermalbonded wadding, chemical bonded wadding.