1. Max. speed is 750 RPM, according to the resistance wire, fabric and pattern complexity, machine speed might be varied.

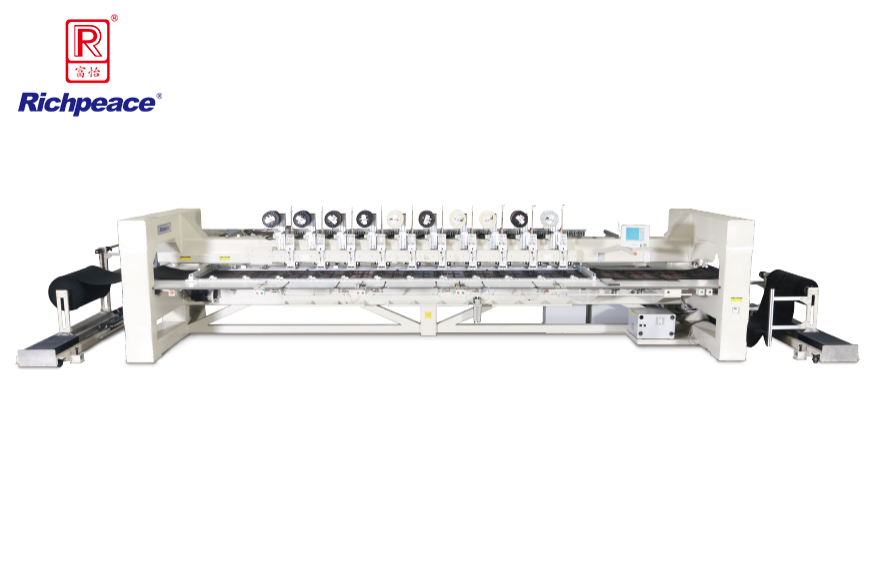

2. Gantry structure: convenient for feeding fabric from left, collecting back in right, ensure fabric is flat without wrinkle during the wiring process.

3. Material maximum thickness can be 5mm, and stitch length can be adjustable from 0.8mm-5mm.

4. Resistance wire with minimum turning radius should be bigger or equal to 3mm. Turning radius can be varied with resistance wire thickness and material type.

5. Automatic wire feeding device "resistance wire or other material" : large wire spool device, reduce the wire refill times during production process.

6. Automatic alarms and machine stops when wire is stuck, needle contacting conductive wire auto-detect alarm and machine stops.

7. Pneumatic frame can be released manually and able to keep pressure when power down occurs.

8. Resistance wire cutter have anti-collision protection (prevent cutter not being returned back and hitting wiring frame.)

9. Bobbin with 2X jumbo bobbin, enlarge bobbin thread capacity, reduce bobbin changing frequency. Increase machine efficiency, reduce operator labor intensity.

10. With zigzag stitches type.