▲

▼

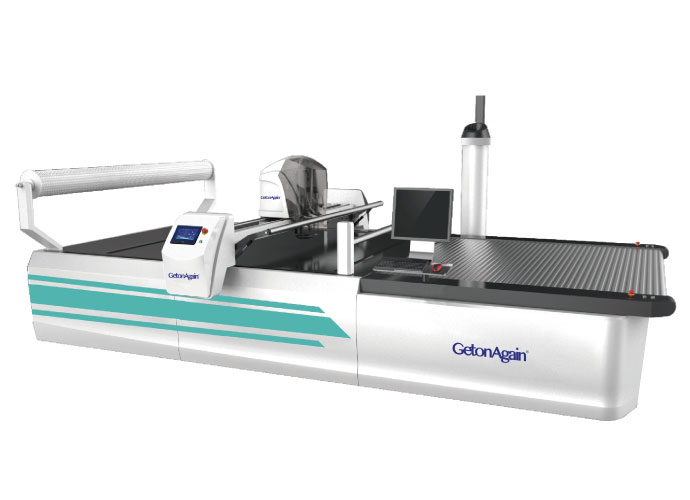

Automatic Multi-layer Cutting Machine

Suitable for efficient cutting of multiple layers of materials in the garment, home textile, and automotive interior industries.

.png)

Please wait a moment. The video is loading...

Equipment Advantages

- Intelligent Cutter: Through the combination of micro-level intelligent sensing components and an intelligent control system, dynamic compensation and correction of cutter deformation during cutting operations are achieved. Significantly reduces errors between the top and bottom layers of fabric during cutting, enabling truly high-precision intelligent cutting.

- Punching Device: Driven by a high-performance servo motor, offers strong penetration capabilities and high stability.

- High-Speed Cutting Head: Cutting head achieves a maximum speed of 6000 RPM, with a maximum cutting speed of 60 m/min., greatly improving cutting efficiency.

- Dynamic Intelligent Sharpening System: Innovatively enables automatic cutter sharpening during cutting head movement, overcoming the limitations of traditional static sharpening. Not only improves sharpening efficiency but also optimizes the sharpening process, extending cutter life and reducing grinding belt consumption costs.

- XY Rack-and-Pinion Gear Driven Structure: Utilizes precisely machined high-fit rack-and-pinion components to ensure efficient, high-precision, and low-noise transmission, ideally for high-speed cutting operations.

- Stable Mechanical and Electrical System: Machine body features an integrated design with excellent rigidity. Equipped with an intelligent servo control system and adopts international famous branded electrical components, ensures stable operation and high performance.

Equipment Models

| Model | Working Area (mm) | Power (kw) |

|---|---|---|

| GOA-AC,NM-MC9-1-2000×1600-SB-MH-NA-3P380 | Working Width:1600mm | 30kW |

| GOA-AC,NM-MC9-1-2000×2000-SB-MH-NA-3P380 | Working Width:2000mm | 30kW |

| GOA-AC,NM-MC9-1-2000×2500-SB-MH-NA-3P380 | Working Width:2500mm | 30kW |

| GOA-AC,NM-MC9-1-2000×2600-SB-MH-NA-3P380 | Working Width:2600mm | 30kW |

×

Related Products

←

Single Layer Cutting Machine

Suitable for cutting various materials including garment fabrics, leather/synthetic leather, soft PVC/rubber, various types of paper, non-metallic films, carbon fiber woven materials, etc.

Automatic Multi-layer Cutting Machine Model MC6-S

Suitable for efficient cutting of multiple layers of materials in the garment, home textile, and automotive interior industries.

Automatic Multi-layer Cutting Machine Model MC8-E

This equipment is suitable for apparel, automotive interiors, home furnishings, and industrial production fields, offering high-precision and high-speed cutting solutions with support for smart production management.

Automatic Multi-layer Cutting Machine

Suitable for efficient cutting of multiple layers of materials in the garment, home textile, and automotive interior industries.

Stripe and Plaid Matching Cutting Machine

Suitable for high-end clothing customization, stripe and plaid fabric cutting, processing of knitted and woven fabrics, as well as leather material handling.

Automatic Multi-layer Cutting Machine Model MC9-E

Apparel Manufacturing, Automotive Interiors, Home Furnishings, Industrial Material Processing, Leather Processing, Composite Material Cutting

→